FORWARD AND AFT OVERHEAD PANEL (UPDATED 22 JUNE 2025)

The forward and aft overhead is probably the most complex panel, both in the real aircraft and in the simulator. Therefore, it has been earmarked to complete at a later stage in the project. I believe it’s wise to have everything else working in the simulator (MIP, avionics, throttle, CDU, etc) with minimal bugs before connecting the forward and aft overhead.

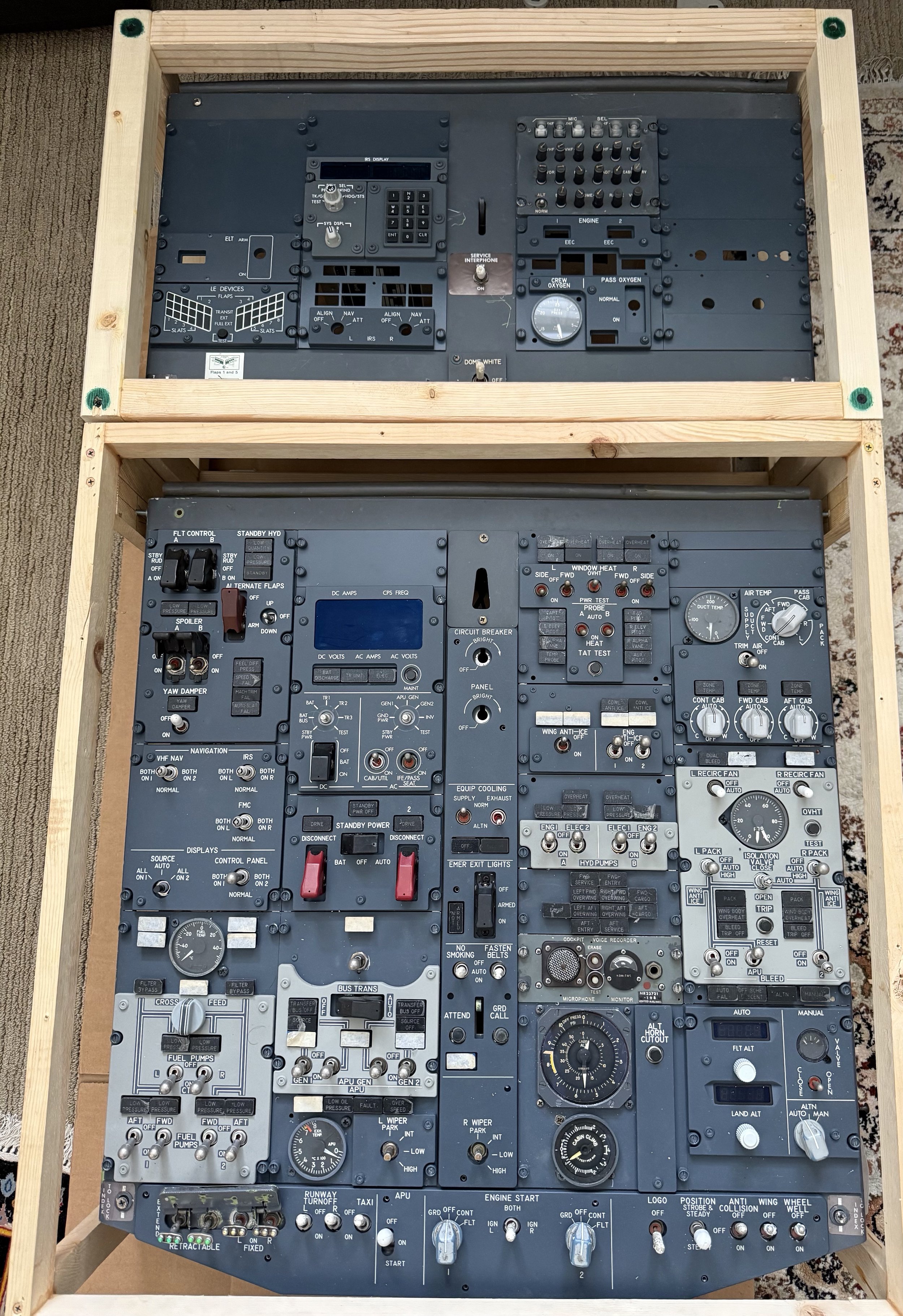

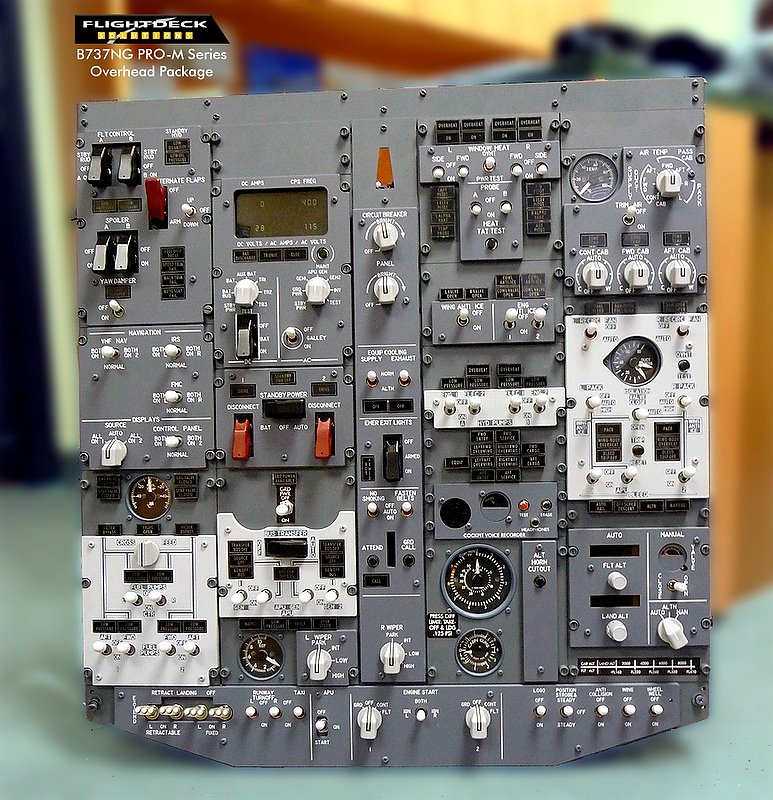

At first, I deliberated using a overhead manufactured by Flight Deck Solutions - mainly because it was ‘plug and fly’ (remember, this was in 2011 prior to OEM components being a feasible option). However, an OEM Boeing 737 overhead frame appeared on the market at a reasonable price, and I was fortunate in securing the forward and aft sections along with Cole starter switches, some gauges, light switch toggles and several other switches and panels. This said, there was still still a number of panels, korrys and toggles missing.

OEM Panels

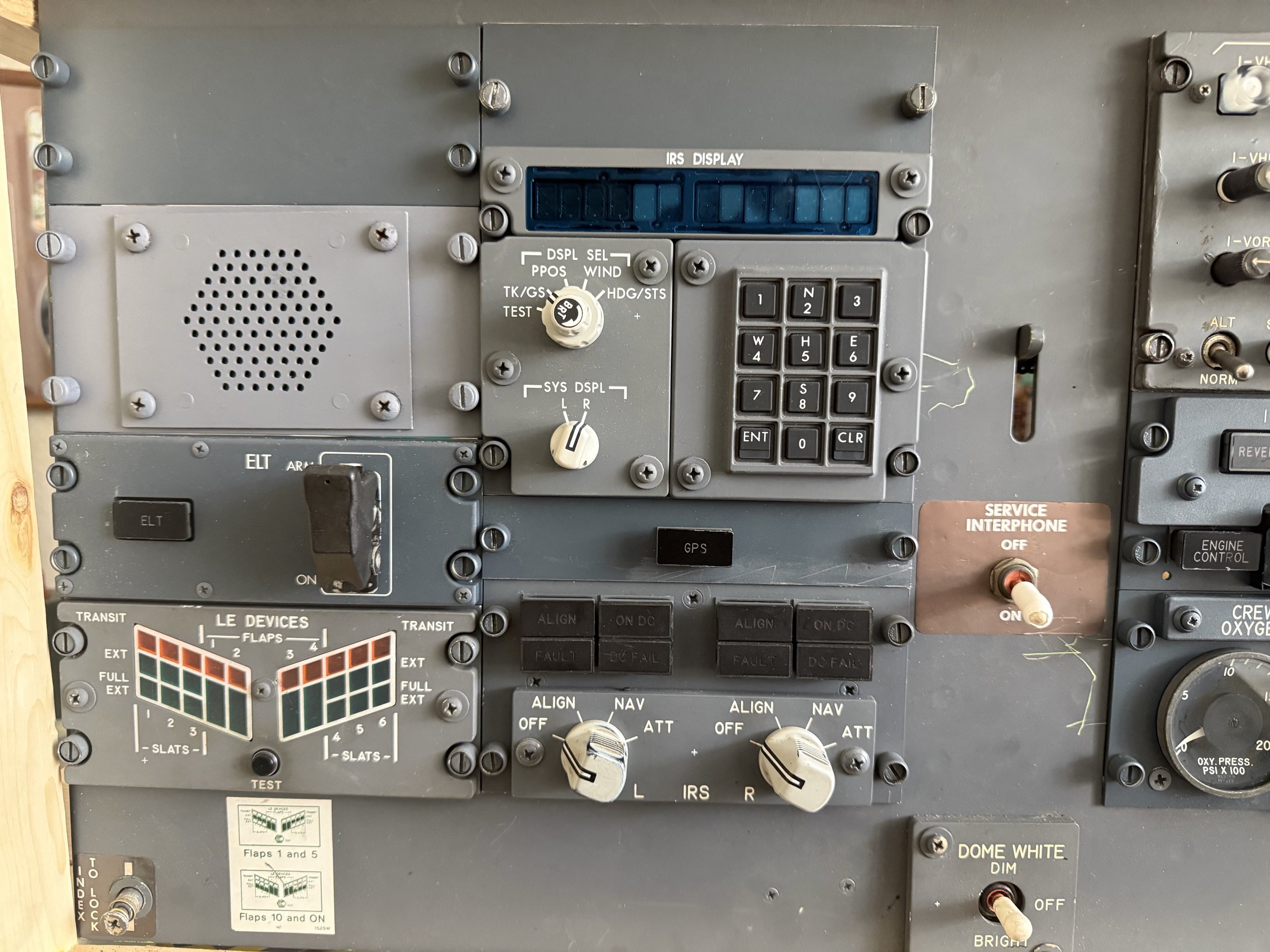

The overhead forward and aft frame (not the panels and gauges) comes from a 737-500 classic series aircraft. There is a difference between the classic overhead and the Next Generation overhead (panels and light plates), but the frames are identical. To this frame various OEM Next Generation panels have be added using DZUS connectors.

Timeline

The overhead is not a panel you can construct in a few days or weeks and finding the correct OEM panels in reasonable condition has taken longer than anticipated. At the beginning of the project I decided that I would not implement an OEM overhead until I had 95% of the panels and gauges.

The simulator is flyable without an overhead, so a time frame has not been set for completion; this is a project that ticks along in the background.

737-800 overhead functionality

Overhead Functionality

The adjacent video provides a good overview of the overhead functionality.

Update (01 June 2025) - Building the Overheads

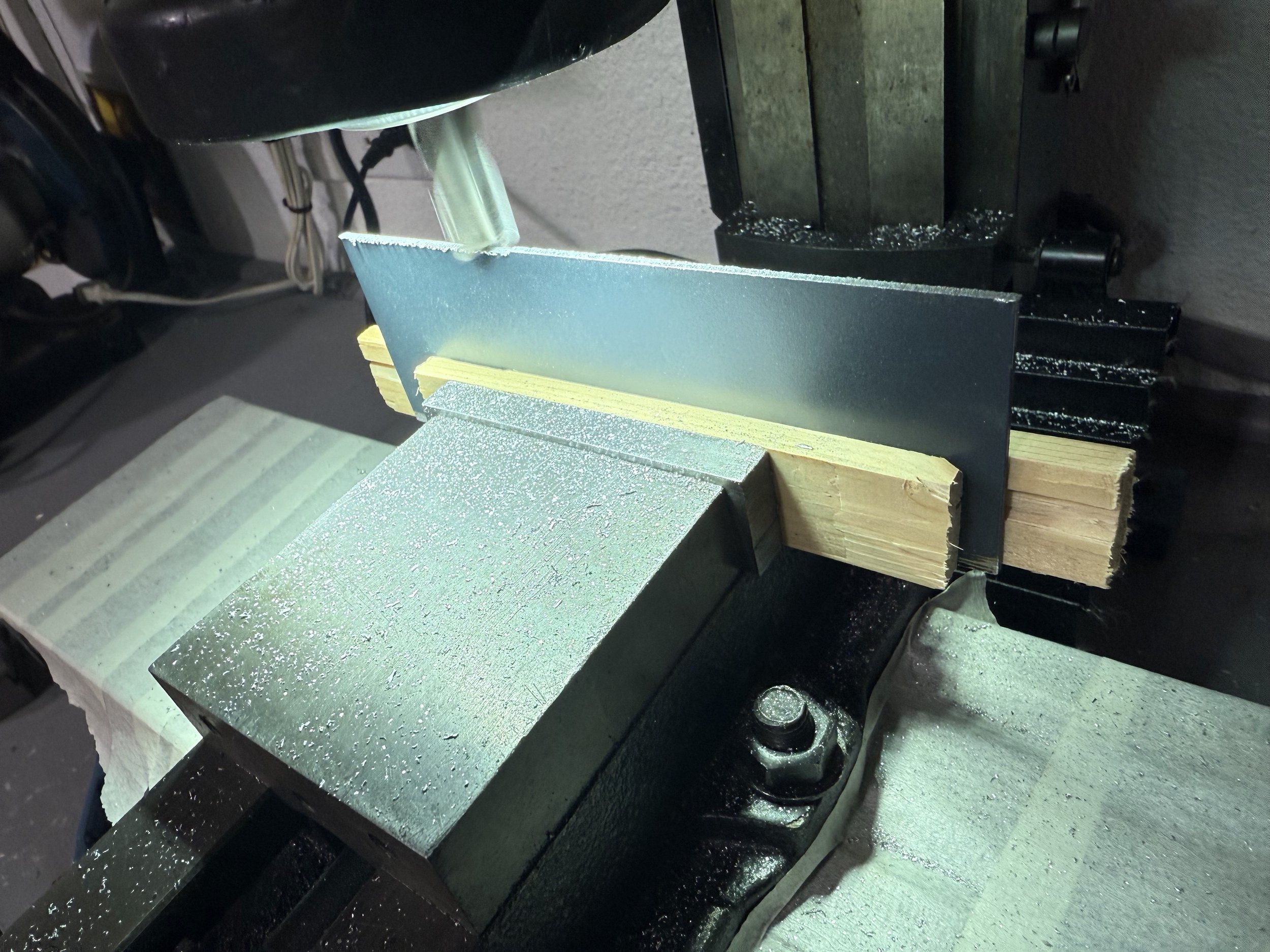

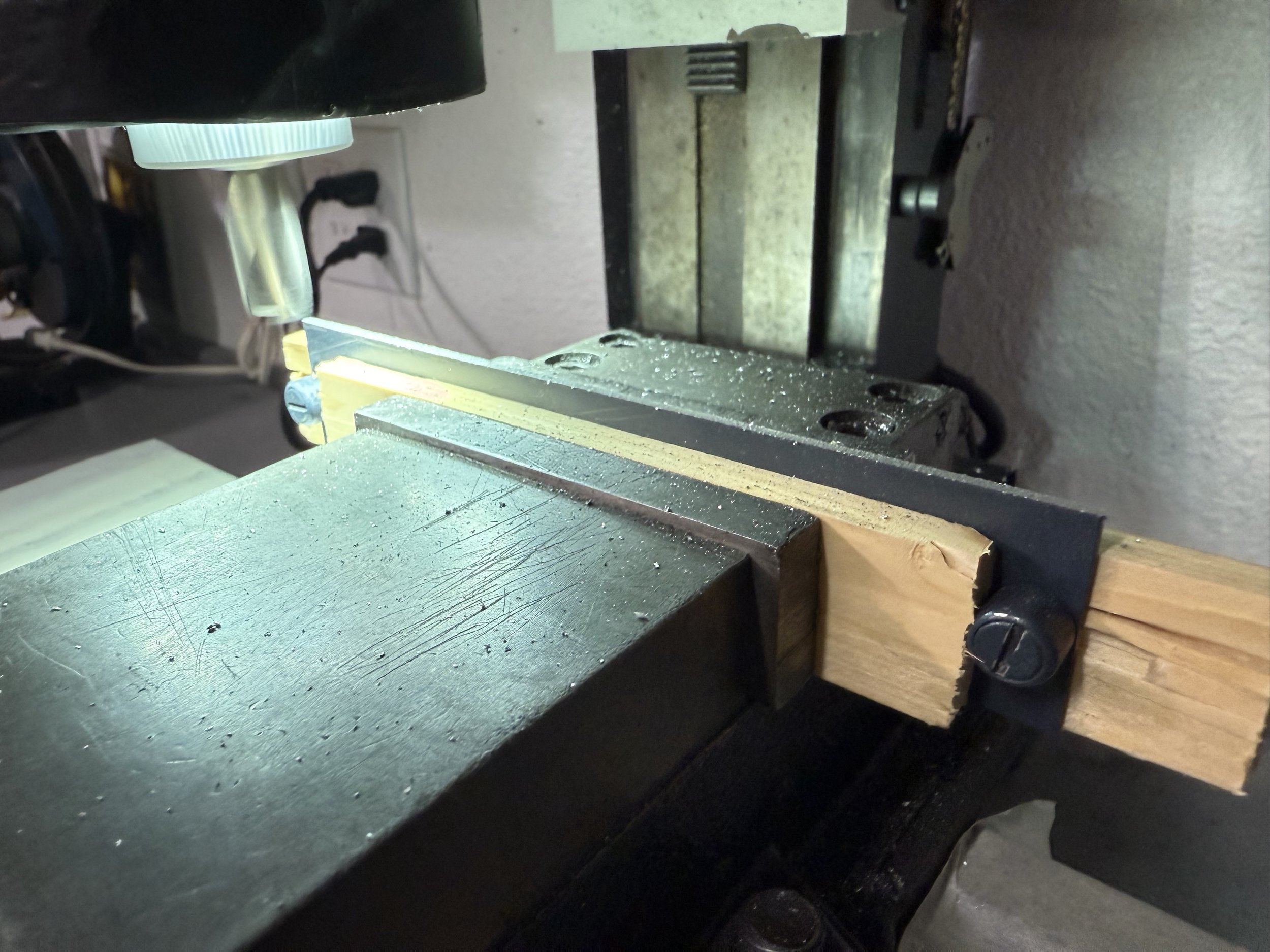

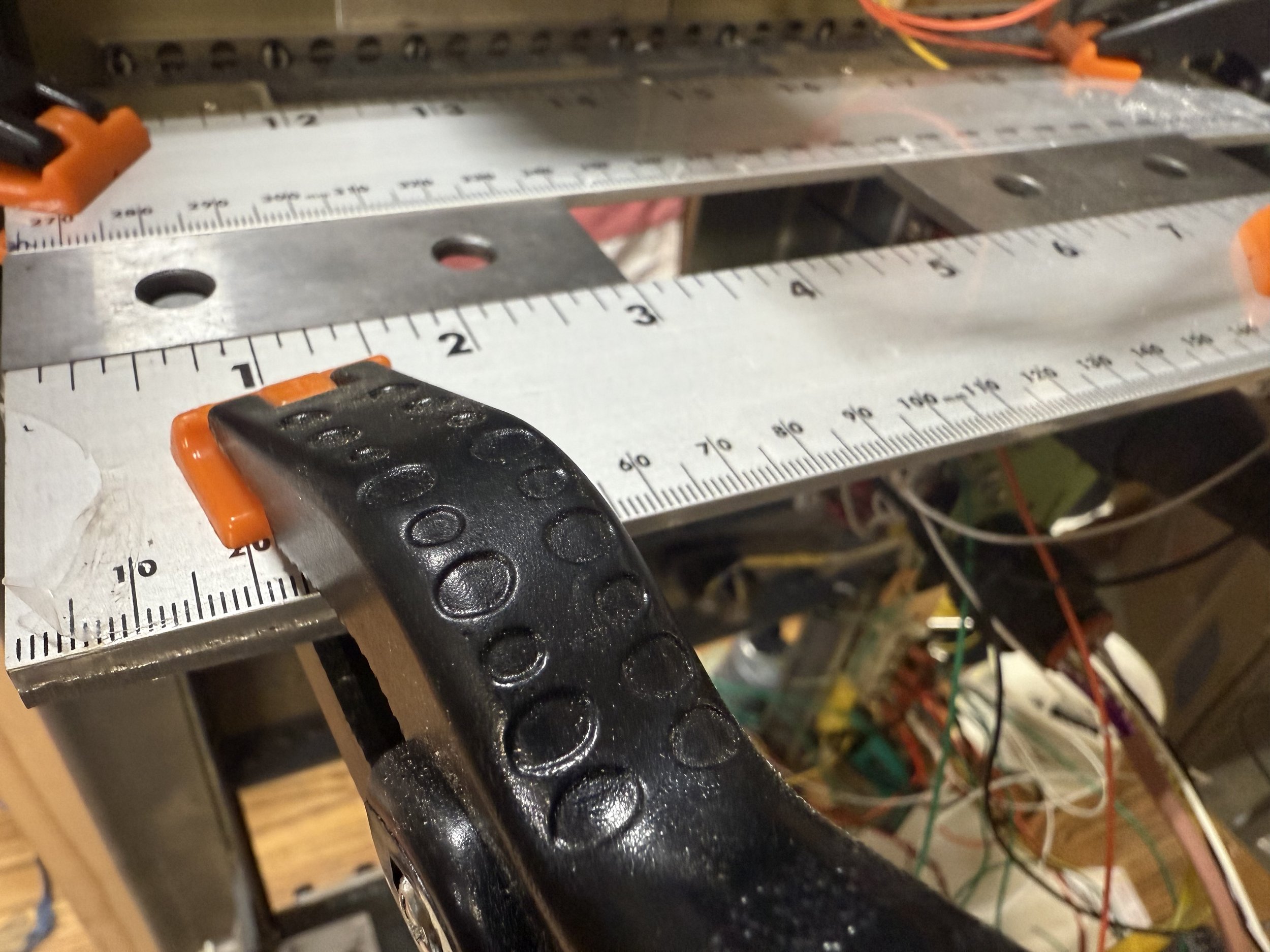

It has taken an inordinate amount of time to find the required OEM panels and Canon plugs, and after several years the forward and aft overhead, with the help of a friend, is being assembled. The OEM forward and aft frame have been temporarily mounted inside a wooden frame to make working on the panel easier.

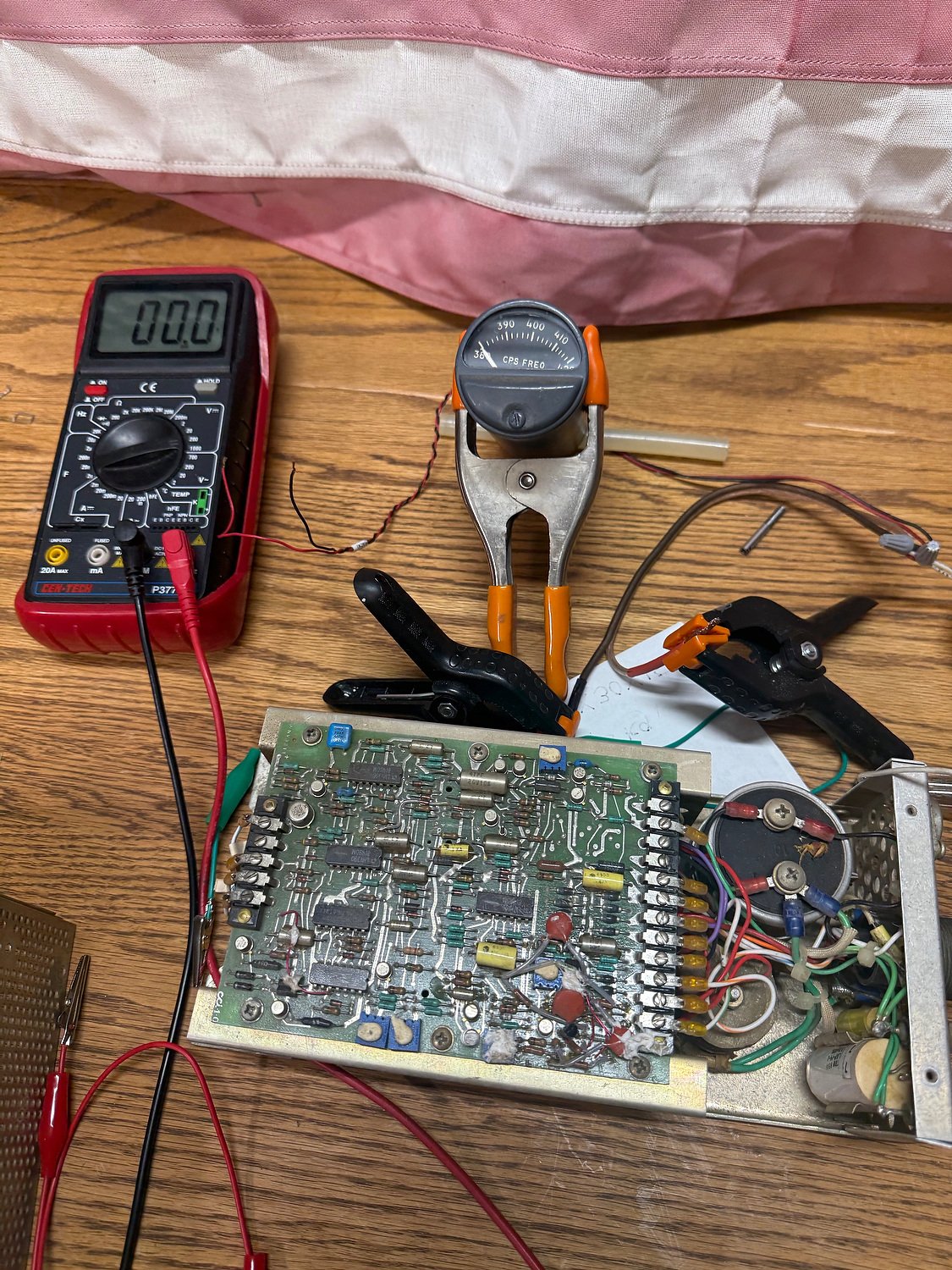

For the most part, the conversion of the panels for use with ProSim737 has been completed using Phidgets and the original avionics, which communicate via the ARINC 429 protocol.

It is hoped that the overhead will completed and be operational by late 2025.

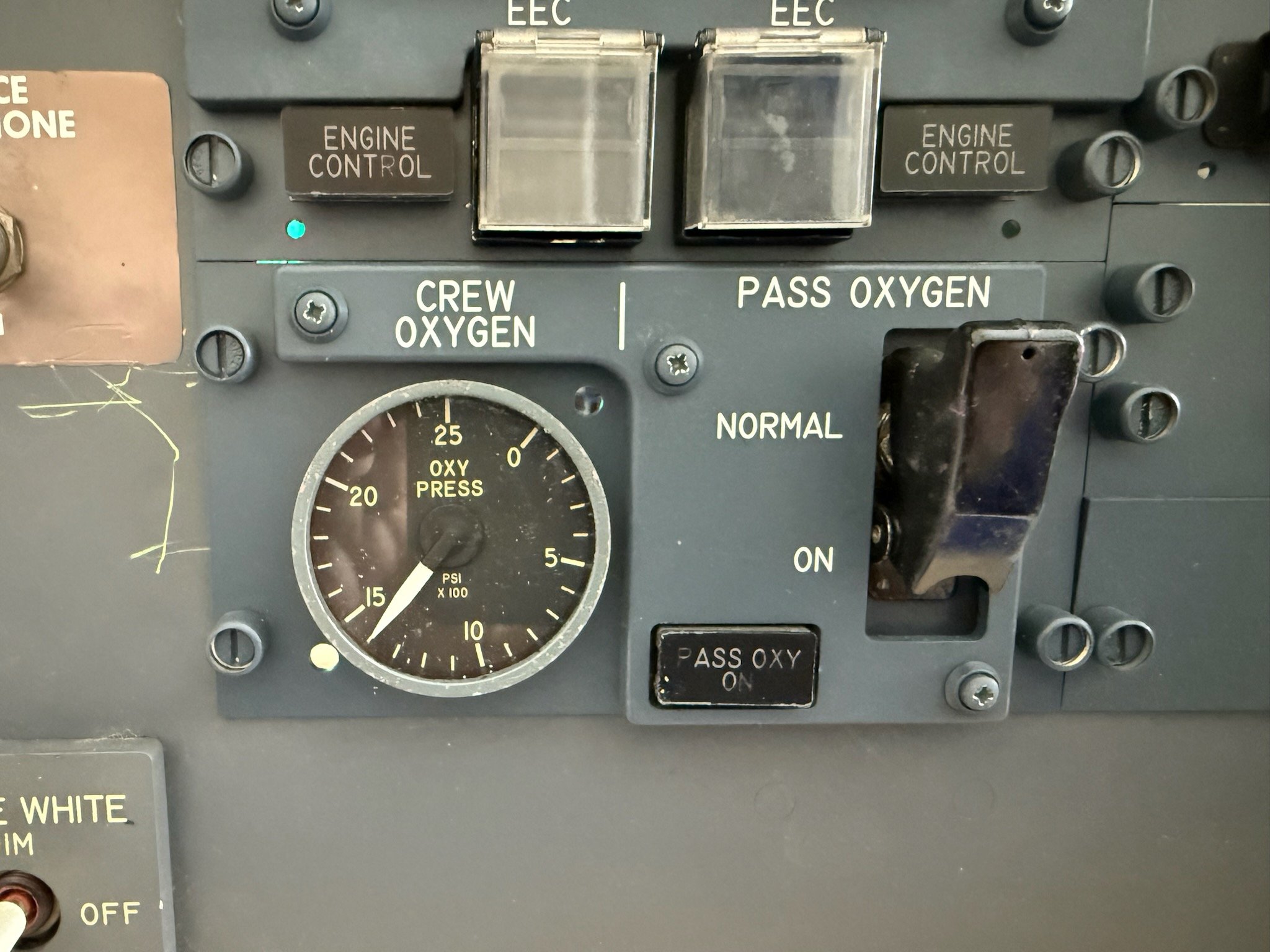

Gallery: OEM Forward and Aft Overhead (during construction phase)

As the overhead build progresses, images and short 'working' videos will be published.

The images and videos in this gallery are preliminary, showcasing the overheads and OEM panels during the build process. Once the overheads are completed, these images will be replaced with higher quality images.

Upon completion, a series of articles will be written to detail the conversion process of the various panels

GALLERY 1: A showcase featuring the various panels and gauges used in the forward and aft overhead during the assembly phase.

Video Gallery: A selection of videos showcasing the verification and quality assurance of various OEM components to ensure proper operation.

Checking amperage draw with lights test enabled on aft overhead

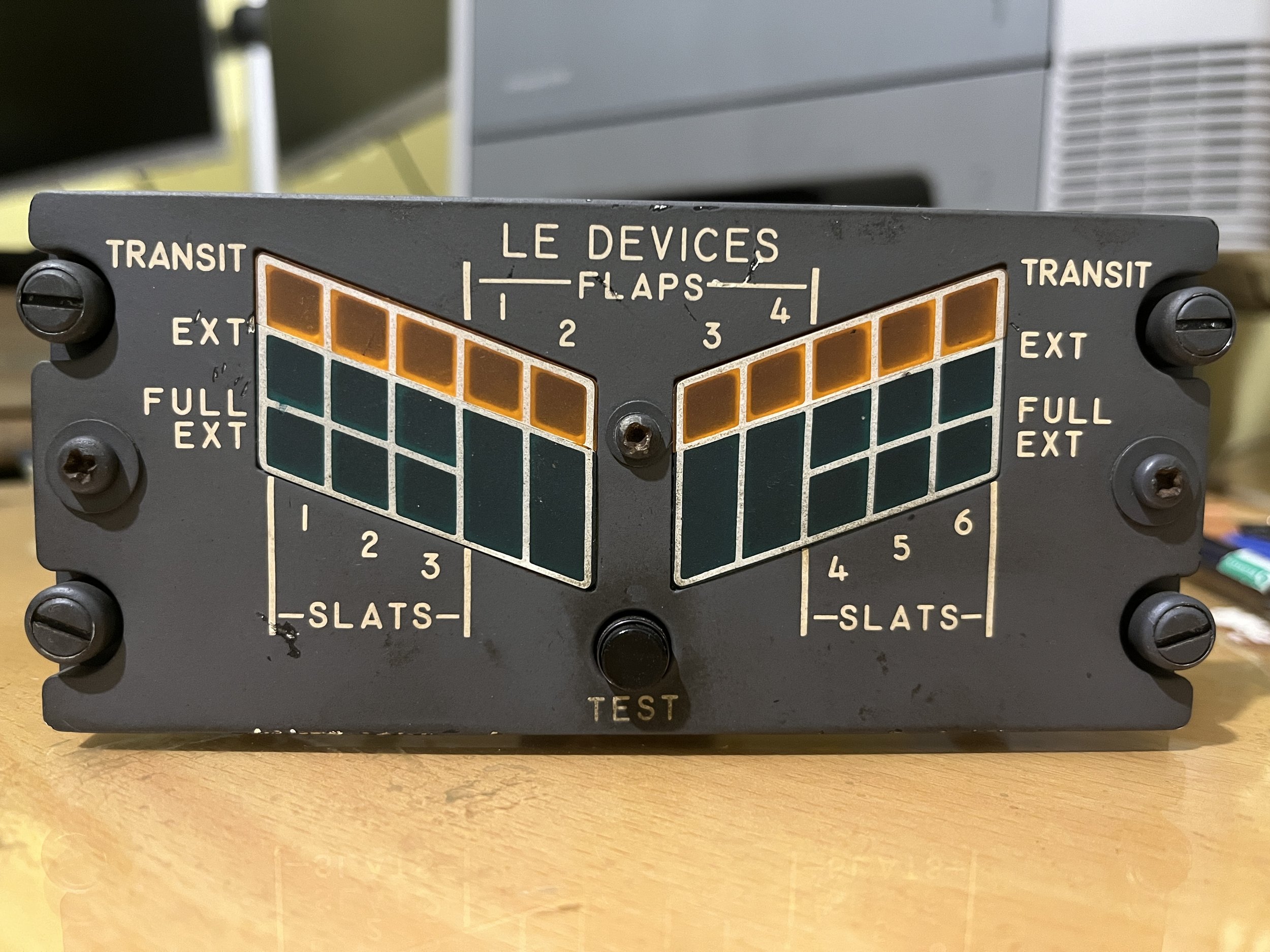

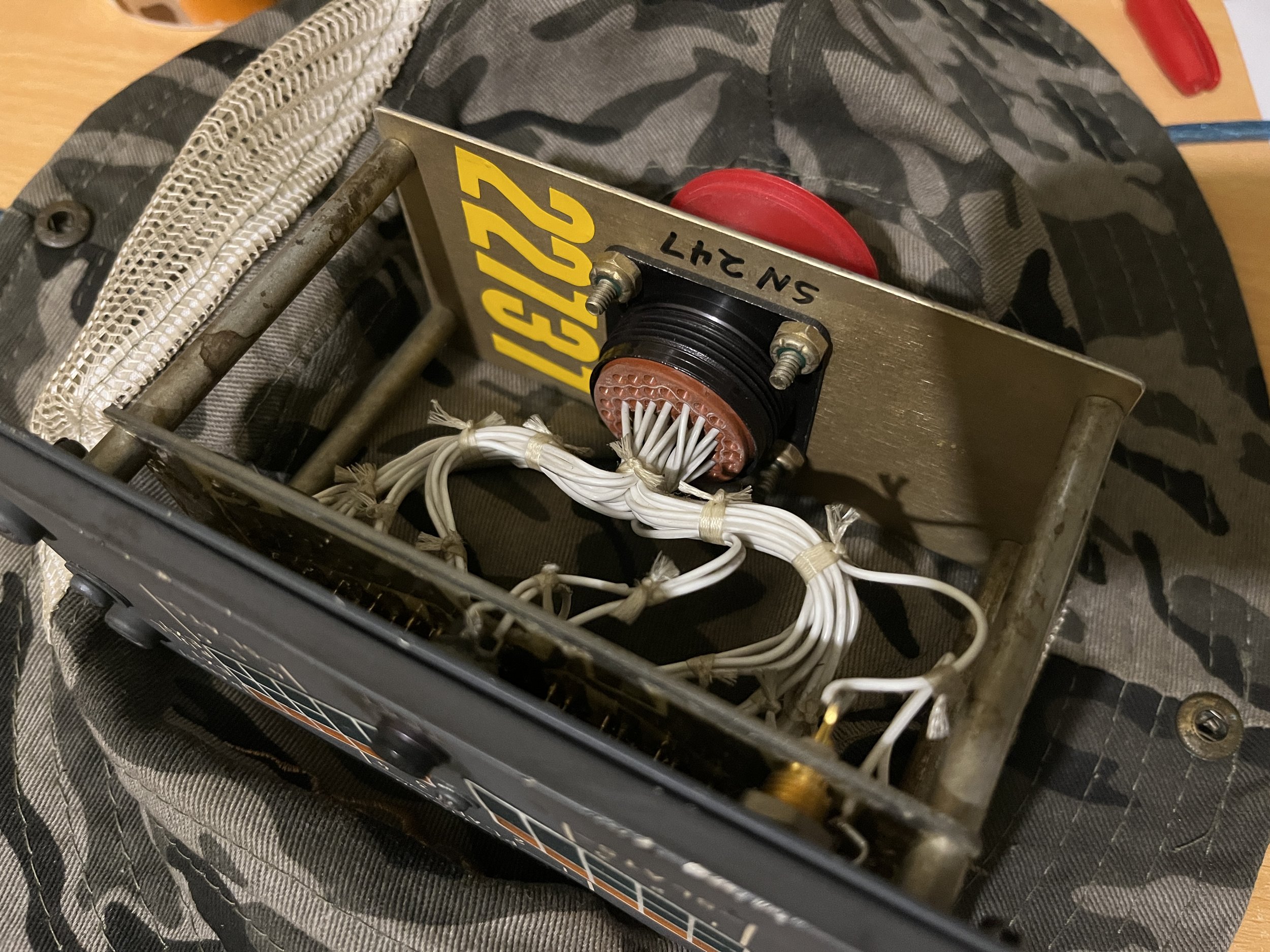

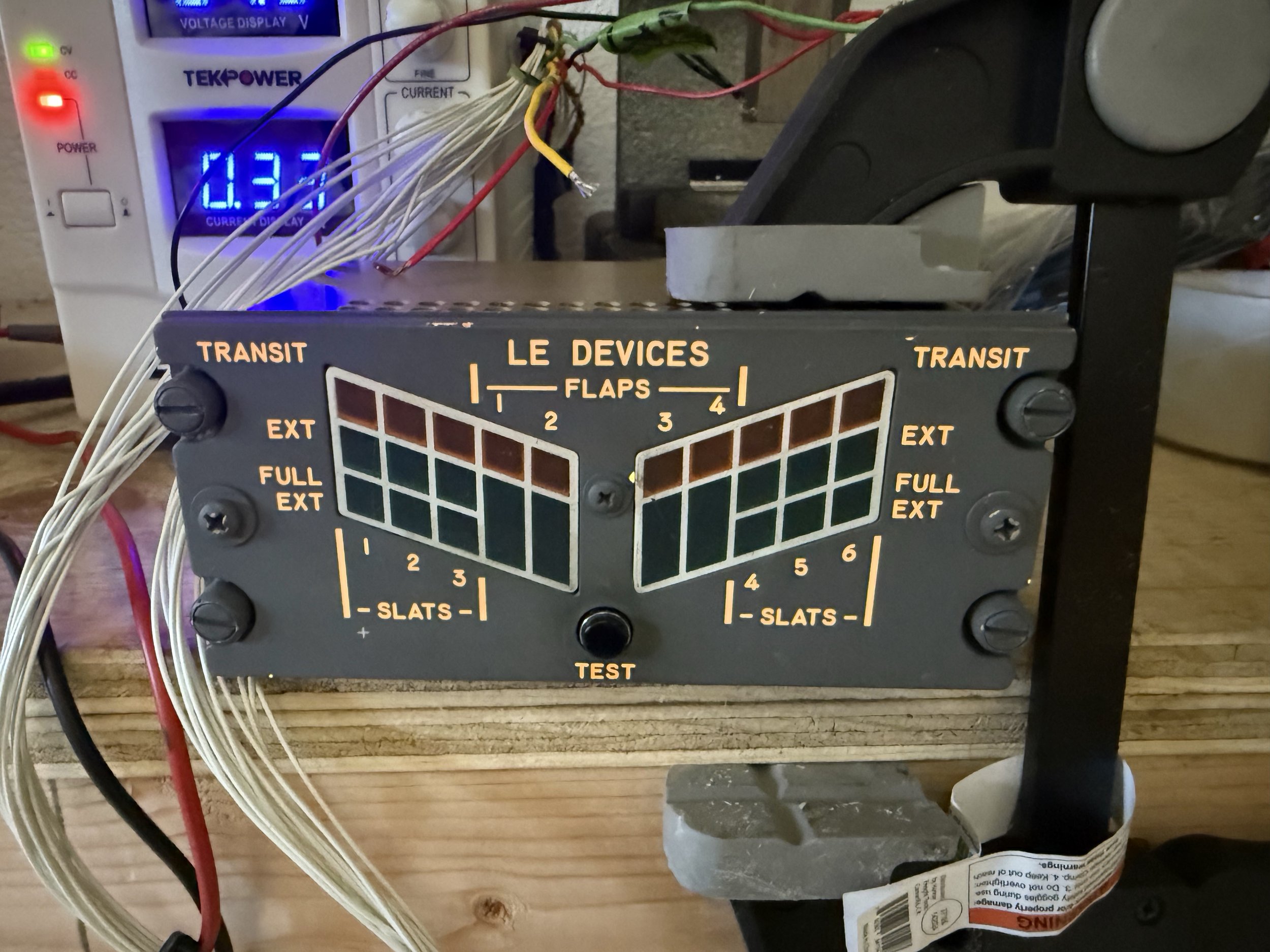

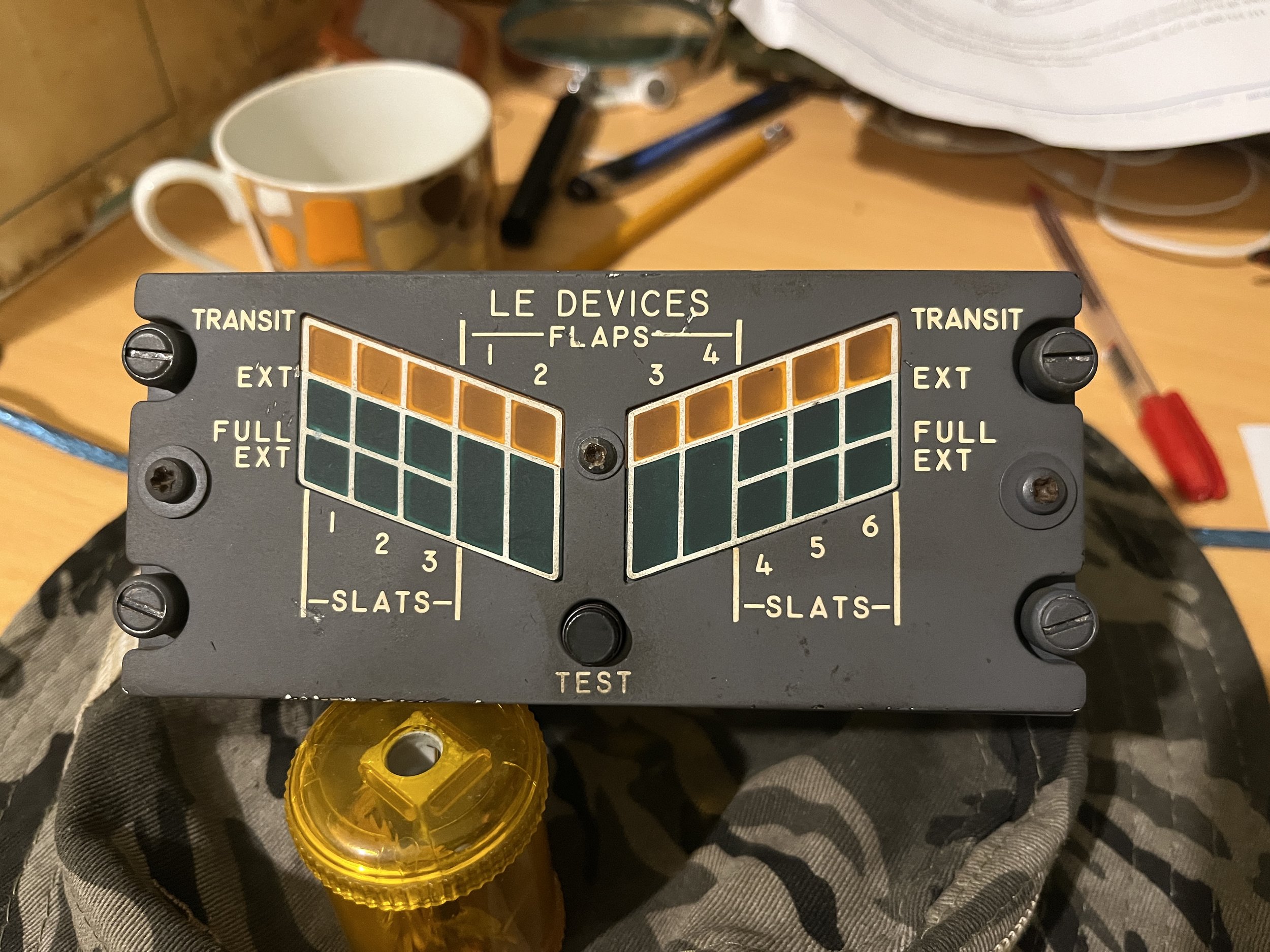

Determining OEM Le Devices Flaps Pinout (dancing lights)

Checking electrical power AC/DC on OEM forward overhead

Cabin Altitude and Cabin Pressurisation Panel - OEM Overhead

Checking Operation - AC/DC Panel, Toggles and Switches - OEM Overhead

Checking start logic on OEM forward overhead

Bright lights test on valve korrys on OEM forward overhead

Checking lights test on OEM aft overhead

Checking Digital Cabin Pressure Control System (DCPCS) - OEM Overhead

OEM cabin climb pressure gauge made operational using a motor controller card (MCC) to connect directly with ambient pressure generated from flight simulator. The use of a MCC does not interfere with the original gauge which can still function if necessary. Gauge is sitting on workbench and needs to be reinstalled into its casing

Checking the needle movement on the cabin climb gauge. The gauge is not yet connected with flight simulator or ProSim737. The needle is being moved by manually engaging the servo motor

Checking Yaw Damper Disconnect - OEM Overhead

Test the dimming of the Grimes 12 volt LED keyhole light. The dim function has been temporarily connected to the circuit breaker panel and will be moved to the center pedestal when the overhead is installed to the simulator

Testing the backlight dimming on the forward overhead using OEM rheostats. The flashing is caused by the video camera

Checking the OEM APU EGT gauge for correct operation and smooth needle movement

Checking smooth needle movement and operation of OEM air temperature gauge with ProSim737

Fine tuning the needle movement and timing between the OEM APU gauge and the OEM EGT gauge with ProSim737

Fine tuning the needle movement of the OEM EGT gauge with ProSim737 before installing the gauge to the overhead

In the Boeing 737, if a cabin altitude warning activates, the flight crew can use the manual outflow valve to regain control of cabin pressurization. The manual mode allows them to control the valve directly, overriding the automatic system and allowing for controlled pressursation

Testing the OEM fuel temperature gauge with ProSim737

Preliminary check of back lighting for OEM gauges after replacement of bulbs

Checking OEM Le Devices flaps panel on aft overhead

Checking alternate flaps on aft overhead

Checking operation of OEM EVAC panel. The audio alarms, however, for some reason the audio file would not upload correctly

Checking the cabin phone panel for correct operation during the lights test. The cabin phone panel is a special order panel that comes standard with 737 Boeing Business Jet (737BBJ)

Testing the OEM cabin pressurization panel for correct operation

Testing OEM IRS with ARINC 429 Protocol

GALLERY 2: A showcase of OEM overhead panels from several Boeing 737 air frames. These images are provided for reference and are copyright to their respective owners.

this page continually being updated