Practical Example

CWS is often used during the climb to altitude with the autopilot being engaged at 10,000 feet.

In the example (left) the aircraft has CWS engaged during climb following flaps retraction. The FMA displays CWS R & CWS P, the vertical speed is 2650 and pitch mode is V/S after changing from TOGA thrust following climb out. Pitch and roll follows the FD bars and speed is 240 KIAS with altitude set to flight level 20900. If CWS remains engaged, the aircraft will continue at this attitude.

Airspeed is not protected when using CWS.

Following rotation, the Flight Director (FD) bars will be followed maintaining V2+15/20 until Acceleration Height (AH) is reached. At AH, the MCP speed will be increased to climb speed, or to a speed as required by Air Traffic Control. As airspeed increases the flaps will be retracted. When the flaps are retracted, the control column will be placed in a position that correlates to the Flight Director bars and CWS A or B will be engaged – the attitude of the aircraft will now be fixed.

The aircraft, in TOGA thrust, will maintain the established pitch as it ascends to the altitude set on the MCP. TOGA thrust is speed protected; therefore, as long as the FD bars are followed there will not be a speed incursion. If a roll mode is selected, the navigational data provided by this mode is also promulgated to the Flight Director. Once the desired altitude has been reached, LNAV / VNAV can be engaged.

Whether a flight crew used CWS is personal preference. Some flight crews use it regularly while others have never used it.

Turbulence (autopilot or CWS)

The Flight Crew Training Manual (FCTM) states:

‘That during times of turbulence the A/P system (CMD A/B) should be disengaged.’

When the aircraft is flying through turbulence, the autopilot is attempting to maintain an attitude (pitch) that is based upon a predefined barometric pocket of air that is present at the altitude you are flying at. In severe turbulence this pocket of air may not be stable and the autopilot will try to change altitude to match the changing barometric pressure. At its worse, the autopilot may unexpectedly disconnect.

CWS provides a stable buffer in which the aircraft will maintain its position when flying through turbulence. When CWS is engaged, it will maintain a preset attitude rather than the A/P attempting to match the attitude to changing barometric pressure.

Flight Crew Training Manuals differ in their content; each manual has been written with a particular airline. Many virtual flyers duplicate the procedures followed by Ryanair. This is because the documentation for Ryanair is relatively easy to find, and the policy of this airline is reasonably conservative. As such, I have transcribed from the Ryanair FCTM the segment on the use of CWS during turbulence.

The Ryanair FCTM states:

‘Flight through severe turbulence should be avoided, if possible. When flying at 30,000 feet or higher, it is not advisable to avoid a turbulent area by climbing over it unless it is obvious that it can be over flown. For turbulence of the same intensity, greater buffet margins are achieved by flying the recommended speeds at reduced altitudes. Selection of the autopilot Control Wheel Steering (CWS) is recommended for operation in severe turbulence’.

The recommended Ryanair procedures for flight in severe turbulence is:

Do not use Altitude Hold (ALT HLD) mode.

Target the airspeed to approximately 280 KIAS or 0.76 MACH, whichever is lower.

During severe turbulence there often will be large and often rapid variations in indicated airspeed. Do not chase the airspeed.

Engage the Yaw Damper.

If the autopilot is engaged, use CWS position, do not use ALT HLD mode.

Disengage the Autothrottle (stops the autothrottle from hunting a desired airspeed)

Maintain wings level and the desired pitch attitude. Use the attitude indicator as the primary instrument. In extreme down and updraft conditions extreme attitude changes may occur. Therefore, do not use sudden and excessive control inputs. After establishing the trim setting for penetration speed, do not change the stabilizer trim.

Autothrottle Use

When CSW is engaged, the autothrottle should not be engaged. The reason for this is because the autothrottle is coupled to the automation, and if there is a change in the aircraft's attitude there will be a corresponding change in engine thrust.

This said, I have spoken with several pilots who claim that they leave the autothrottle on when using CWS. In some respects it depends on the severity of the turbulence encountered.

Lazy Flying

Although not sanctioned by Boeing, some pilots use CWS as a 'lazy way' of flying, whereby they may establish the aircraft at a specific attitude and vertical speed with the autothrottle engaged. As CWS is a sub-set of the autopilot system, trim control will still be controlled by the system and the aircraft will maintain the desired attitude until CWS is cancelled.

A Virgin First Officer has stated that, after takeoff and flaps retraction, she will often use engage CWS to climb to a specific altitude, then she will engage LNAV, VNAV and the autopilot.

It's important to realise there are many ways, (although not sanctioned by Boeing or a specific airline policy) to fly the Boeing 737 aircraft.

Important Point:

Technical Data (general)

The Flight Crew Training Manual states:

‘After autopilot engagement, the airplane may be manoeuvred using the control wheel steering (CWS) pitch mode, roll mode, or both using the control wheel and column. Manual inputs by the pilot using CWS are the same as those required for manual flight. Climbs and descents may be made using CWS pitch while the roll mode is in HDG SEL, LNAV or VOR/LOC. Autopilot system feel control is designed to simulate control input resistance similar to manual flight.'

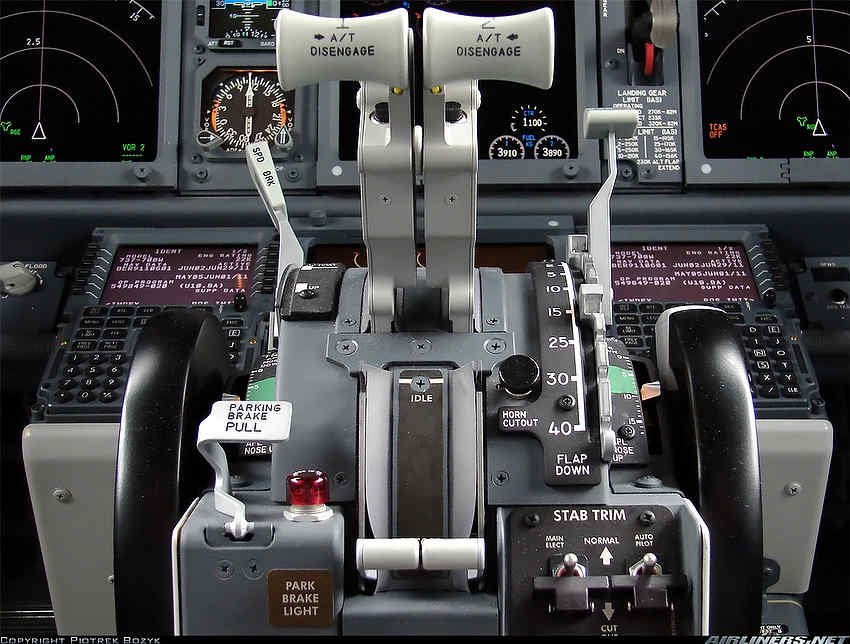

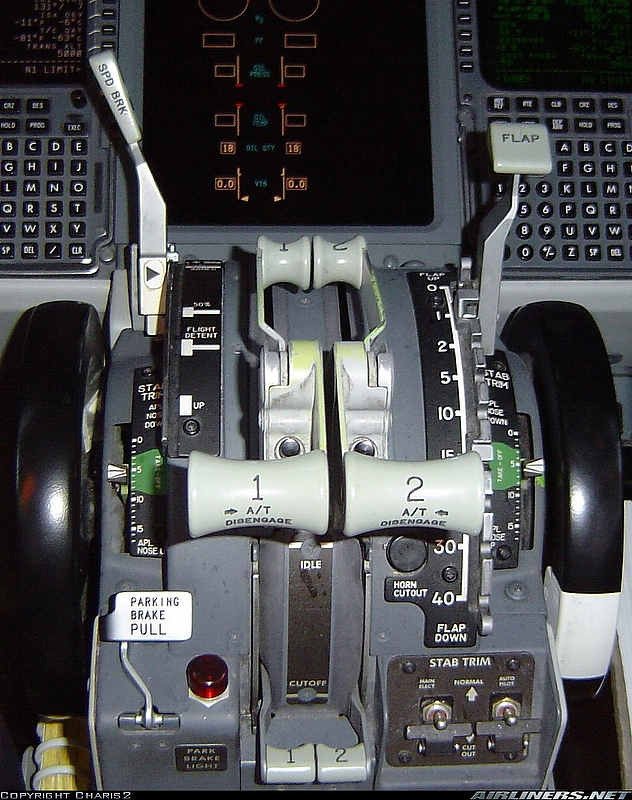

The Mode Control Panel (MCP) has two CWS buttons located on the First Officer side of the MCP beneath the two CMD buttons (CMD A/B). Like the autopilot, CWS has a redundancy system (system A or system B). By default the CWS system is off (annunciator is not illuminated).

The CWS system has been designed so it can be used with or without the autopilot.

To engage the CWS system, either of the two CWS buttons must be pressed. When engaged, the CWS annunciator will illuminate green and the Flight Mode Annunciator (FMA) on the Primary Flight Display (PFD) will annunciate CWS P and/or CWS R.

CWS cannot be engaged when any of the following conditions are met:

Below 400 feet.

Below 150 feet RA with the landing gear in the down position.

After VOR capture with TAS 250 kt or less.

After LOC capture in the APP mode.

Important Points:

Operation - What CWS Does

As mentioned, the CWS system can be used with or without the autopilot being engaged.

CWS can be engaged two ways. Either by moving the control column when the autopilot is engaged, or by pressing the CWS button on the MCP.

To use CWS in its own right, the autopilot must be disengaged. This can be done manually by pressing the CMD button or by pressing CWS; the later will disconnect the autopilot (the CMD annunciation will extinguish and the CWS annunciation will illuminate). To access the CWS system partially, and still use the autopilot, the control column is moved (pitch/roll) while the autopilot is engaged.

Although the CWS concept is easy to understand, documenting exactly what it does is difficult and this can cause confusion. I wouldn't become too concerned with the 'technical jargon' below, as CWS is easy to master by using the function and remembering what it does:

The following information has been edited from documentation acquired from Smart Cockpit Airline Training.

1: CWS selected - PITCH and ROLL (autopilot not engaged)

Depressing the CWS button on the MCP engages the autopilot pitch and roll axes in the CWS mode. It also displays CWS-P and CWS-R on the FMA on both the Captain and First Officer Primary Flight Displays (PFD). (Note that CMD is not selected and the CMD annunciation is extinguished on the MCP).

With CWS engaged, the autopilot maneuvers the aircraft in response to control pressures applied to the control wheel or column. The control pressure is similar to that required for manual flight. When control pressure is released, the autopilot holds existing attitude and roll.

• If the column pressure is released with a bank angle 6 degrees or less, the autopilot rolls the wings level and holds existing heading. This feature is inhibited when any of the following conditions are met:

(i) Below 150 ft RA with the landing gear down;

(ii) After F/D VOR capture with TAS 250 kt or less; and,

(iii) After F/D LOC capture in the APP mode.

2: Moving control column - PITCH (autopilot engaged)

The pitch axis engages in CWS while the roll axis is in CMD when:

(i) The autopilot pitch has been manually overridden with control column force and the force required for override is greater than normal CWS control column force. Note that manual pitch override is inhibited in the APP mode with both autopilots are engaged (autoland).

Important Points:

When approaching a selected altitude in CWS-P with the A/P in CMD, CWS-P changes to ALT ACQ and, when at the selected altitude, ALT HOLD engages.

If pitch is manually overridden while in ALT HOLD at the selected altitude, ALT HOLD changes to CWS-R If control force is released within 250 ft of the selected altitude, CWS-P changes to ALT ACQ and the autopilot returns to the selected altitude and ALT HOLD engages. If the elevator force is held until more than 250 ft from the selected altitude, pitch remains in CWS PITCH.

3: Moving control column - ROLL (autopilot engaged)

• The FMA will display CWS-R.

The roll axis engages in CWS while the pitch axis is in CMD when:

(i) The pitch has been manually overridden with control column force and the force required for override is greater than normal CWS control column force.

Important Point:

With CWS-R selected and the autopilot engaged, the aircraft will capture a selected radio course while the VOR/LOC or APP mode is armed. Upon intercepting the radial or localizer, the F/D and autopilot annunciation changes from CWS-R to VOR/LOC engaged and the autopilot tracks the selected course.

Using CWS (with the autopilot engaged) - Simplified

This segment has been added in response to some readers who stated they had difficulty in understanding some of the above content. I hope it explains, in easier terms, how the CWS system can be used when the autopilot is engaged.

Moving the flight controls (pitch/roll) during automated flight will cause the CWS system to engage. However, the autopilot (CMD) will remain selected and the CMD annunciator will remain illuminated on the MCP.

Flying the aircraft in this manner can be useful when hand flying an approach, but wishing to follow the automated inputs from the ILS and/or FMC.

During such a procedure the following will be noted:

Moving flight controls left or right (roll):

(i) The autopilot annunciation will remain illuminated;

(ii) The FMA on the PFD will alter from CMD to CWS-R;

(iii) The AFDS will illuminate A/P P/RST; and,

(iv) The heading annunciation on the MCP will extinguish, as will the LNAV annunciation if engaged.

The aircraft can now be flown using control wheel steering. To return to fully automated flight, press the heading button on the MCP. LNAV, if used, will also need selecting.

Moving flight controls up or down (pitch):

(i) The autopilot (CMD A/B) annunciation will remain illuminated;

(ii) The FMA on the PFD will alter from CMD to CWS-P;

(iii) The AFDS will illuminate A/P P/RST; and,

(iv) The heading annunciation on the MCP will extinguish, as will LNAV annunciation if engaged.

Important Point:

Final Call

The use of CWS is very much underused and under-appreciated - whether used as a stand-alone system, or in conjunction with the autopilot.

Although surface control loading in a simulator rarely matches that of a real aircraft, the use of CWS in a simulator environment can still have positive benefits equating to better aircraft handling, especially when flying circuits and flying in turbulence.