Are You Protected - Power Surges

/The power requirement, or more to the point the regulation of the power is often overlooked when building a functional flight deck.

A basic desktop-style simulator controlled by a single computer and displayed on two computer monitors will draw very little power and can easily be connected to a single household wall socket. However, as a simulator build becomes more complex and incorporates multi-displays and various other pieces of equipment the power requirements become more complex.

In this post, I will discuss the basics surrounding the distribution of power, in particular amperage draw. I will also address the need for surge protection.

This post is an introduction into the somewhat confusing and complicating world of electricity and power quality; it is not intended to be a definitive work.

Amperage Draw

The biggest issue with many simulators is amperage draw, with many builds drawing close to, if not over 10 amps. Drawing in excess of 10 amps can cause a standard household circuit breaker (or fuse) to be triggered cutting off the electricity supply to the simulator.

Although a power shut down from the triggering of a circuit breaker can be annoying, especially if part way through a simulator flight, a bigger problem is that many interface cards including Phidget cards may lose important configuration and calibration parameters if they are ‘murdered’1by a power shutdown.

Amperage Draw, Circuit Breakers and Zones

The power distribution in a modern house is distributed into zones (circuits).

A zone will have any number of power points attached to it, and will be protected by a dedicated circuit breaker of specific amperage. For example, water and heat is one zone, while lighting and power points can be spread across one, two or more zones (depending on the number of lights and their respective amperage draw).

In Australia, all standard household power points (except heat and water) are rated at 10 amps while the wire that runs from the power point to the circuit board is rated at a higher capacity; usually 15 amps.

If the power requirements exceed 10 amps within a zone, then the circuit breaker on the circuit board will be triggered and the electricity will cease to flow into that zone.

Many will be accustomed to this inconvenience, when they have a number of heaters plugged into various power points within one zone. Turning on the kettle to boil water, will then be enough to exceed the power amperage for that zone and the circuit breaker will be triggered.

My next post will take a more detailed look at circuit breakers and the types that can be used in various situations, so more more on this later.

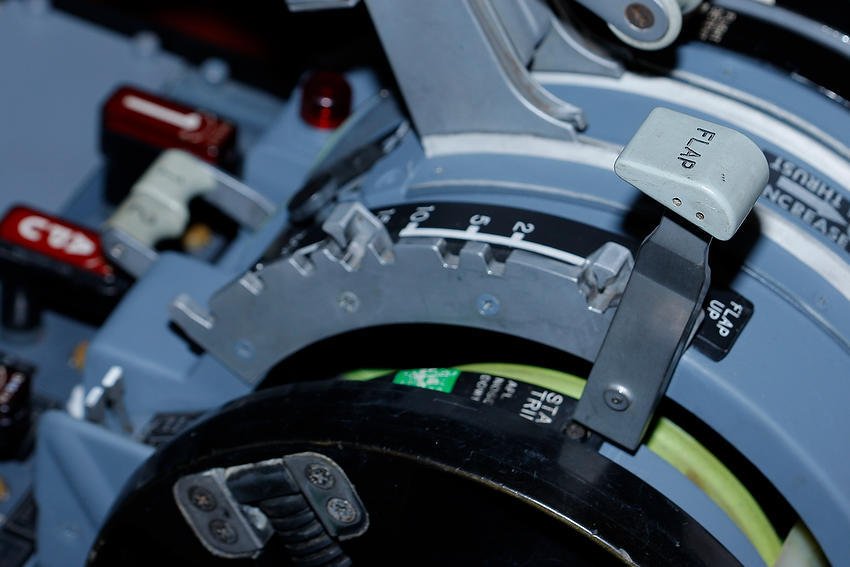

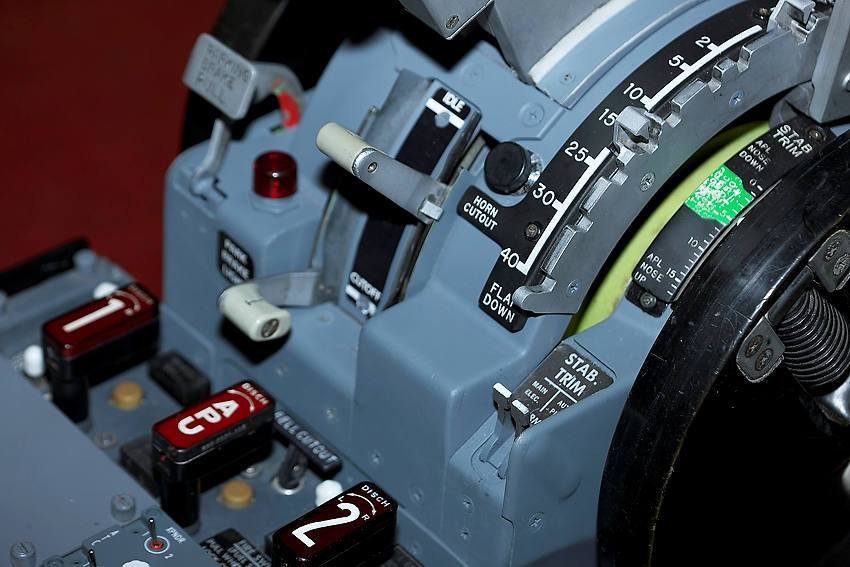

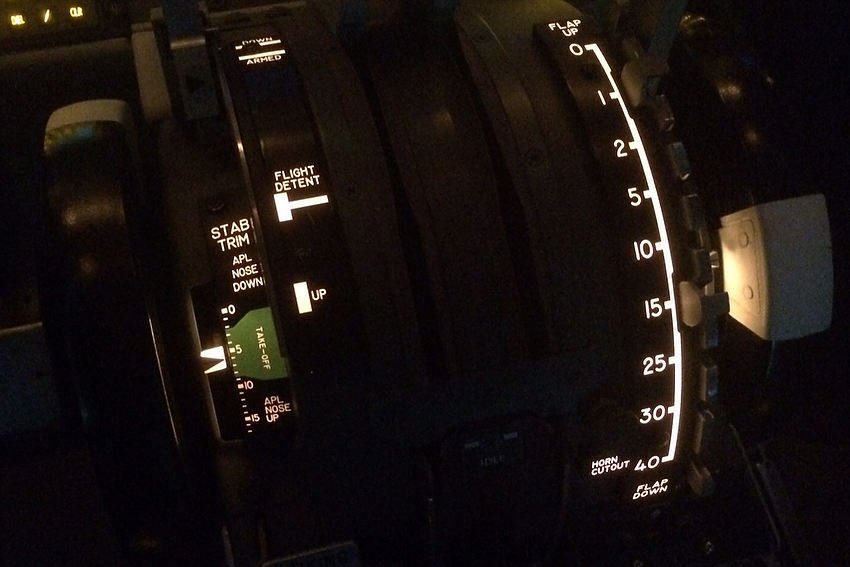

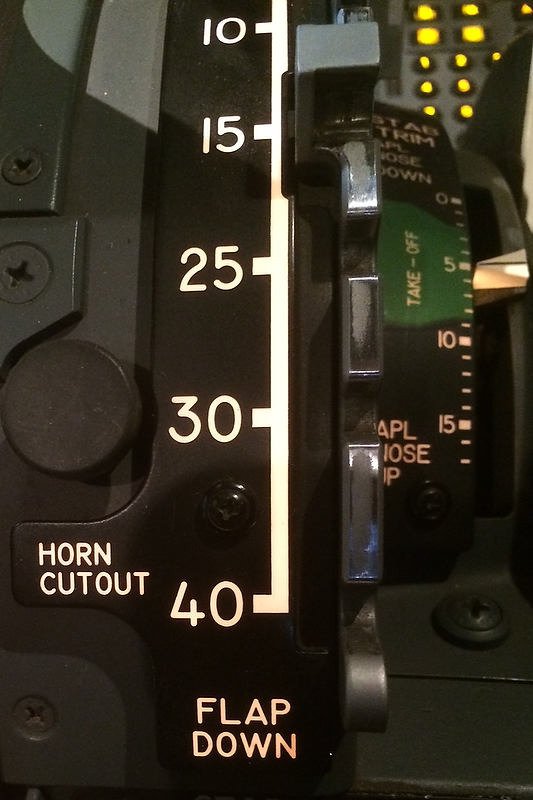

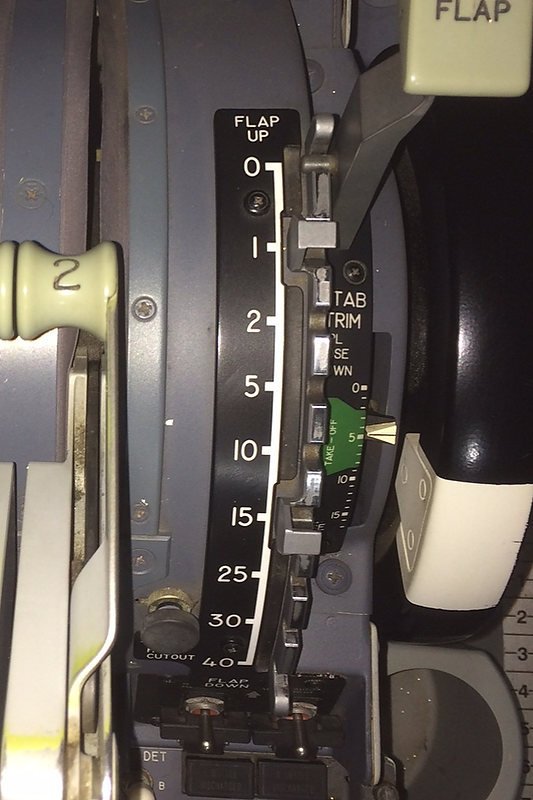

Amperage draw and status can be measured if an appropriate gauge is installed and the wiring connected correctly. The gauges in the picture are measuring amperage status of different sectors (5 & 12 volt sectors) in the Throttle Interface Module

Amperage Draw and Heat

An easy method to enable a greater amperage draw is to replace the 10 amp circuit breaker with one rated at a higher capacity. This will alleviate the situation of the circuit being tripped every time you exceed 10 amps. Whilst this is feasible, after all the wire running between the board and the power point is 15 amps, it is not recommended.

A by-product of drawing too many amps along one wire is heat, and although the wire may be rated at 15 amps, the heat may cause electrical wrapping to begin to melt. Furthermore, if the amperage draw is maintained the power point may begin to melt and burn due to the exceeded amperage draw.

Calculating Amperage Draw

Calculating the amperage draw can be complicated as equipment can draw different amperage at different times. For example, a computer when turned on will initially draw more amperage; however, this draw will lower after the initial start cycle has been completed.

Often, you can cause an over-amperage draw that triggers a circuit breaker by starting everything simultaneously. To minimise this occurring, it is best to start different systems sequentially keeping the amperage draw to a minimum and below the 10 amp rating of the circuit breaker.

Upgrading the Amperage

If the simulator (or any number of electrical appliances) draws more than 10 amps, and the circuit breaker continuously is triggered, there are two methods in which to solve the problem.

First, is to have an electrician replace the wire for the zone that the simulator is connected to. This involves replacing the 10 amp power point with a power point rated at 15 amps, running higher capacity wire between the power point and circuit breaker, and using a higher amperage circuit breaker in the circuit board. A 15 amp power point also incorporates a larger blade assembly (earth) on the plug..

The second method is to spread the power requirements over two or more zones. This way, if the simulator operates across two 10 amp zones you will have 20 amps of power available.

The downside of the second method is that you will need to have power points in close proximity to each other that connect to two zones; otherwise, an extension cable may need to be run between the simulator and the designated power point.

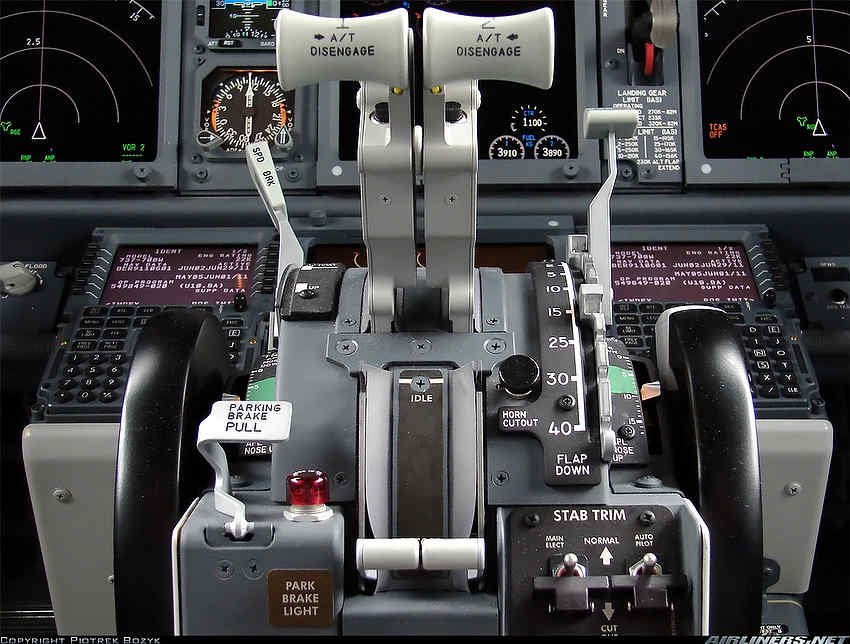

Sine wave data read-out showing the tell-tail spike of a power surge

Power Surges, Noise and Clean Power

Unfortunately, power is not clean and everyone will experience at sometime or another voltage fluctuations (power surges). The severity and frequency of the fluctuations will depend upon the ability of the power grid to obtain, store and distribute power.

The power requirements of a large industrial complex powering on in the morning maybe enough to cause a fluctuation (surge) as it draws initial power from the grid. Furthermore, surges in power can often occur when the electrical company adjusts the grid to take into account the day and night-time power requirements of the surrounding region.

Whilst these are standard day to day activities, a major disruption in power, with resultant surges and spikes, can occur during severe storm events. During such events, power disruptions can be common as poles and wires are damaged due to high wind and torrential rain. In the most extreme case, an electrical discharge from lightening can occur directly on your home or in an area nearby. If your house is struck by lightning, then there is very high chance that permanent damage will result to any plugged in equipment.

Is this problematic – yes and no. An odd low level minor surge will probably not cause too much grief; however, a high volume power surge or a constant surge can damage equipment.

A high-end simulator usually incorporates numerous interface cards, system boards and other delicate components which, more often than not, are not amiable to power surges.

A high volume or constant power surge may destroy the motherboard, power supply and USB PCI cards in the computer, in addition to destroying interface cards attached to the computer. However, minor power surges may not enlist any observable damage (other than the lights flickering or dimming briefly), but they may shorten the effective life of attached components leading to premature burnout.

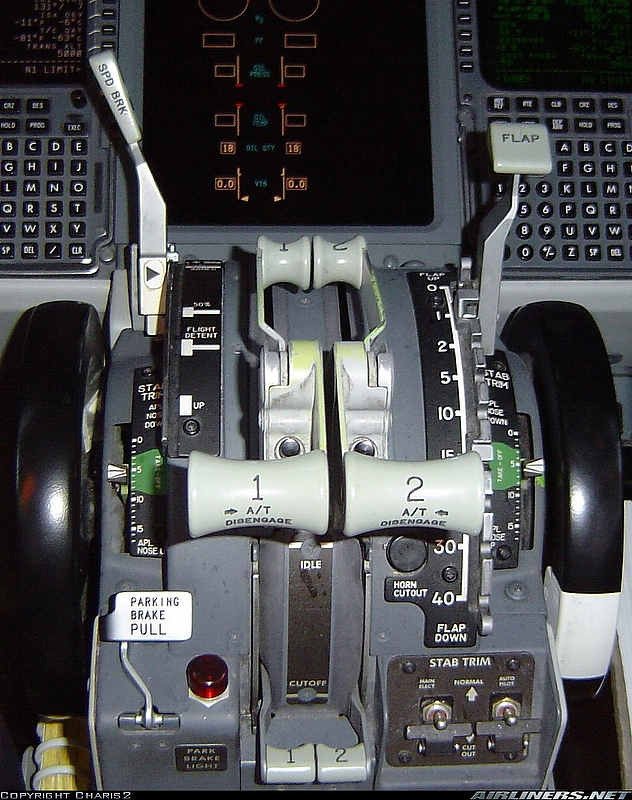

Six plug power surge protection board with internal circuit breaker manufactured by Belkin. Two LED lights indicate on/off and earth leakage while the circular black pop out switch is a standard-type circuit breaker. The Belkin is probably one of the more popular boards and provides average protection with a rating of around 600 Joules (depends on model)

Surge Protection and How It Works

There are several pieces of equipment that can be used to protect electronic equipment; the most common being a surge protector board.

In essence, a surge protector board is a glorified power board with some type of mechanical mechanism that is either destroyed or partly destroyed when a power surge occurs. Higher end protectors may also provide noise filtering and a internal circuit breaker.

The level of protection provided by a surge protector is, at its bare minimum, determined by the level of Joules the board is rated at. Joules (J) is a derived unit of energy as defined by the International System of Units and should be thought of as a reservoir of protection.

Simply put, a board rated with a high number of Joules has a larger reservoir and therefore provides greater protection for a longer period of time. For example, if a board is rated at 525 Joules, the board will provide protection for either one power surge rated at 525 Joules or any number of smaller power surges below 525 Joules until the rating is exceeded.

The design of the board is such that once the level of protection (Joules) has been exceeded, the board will need to be replaced.

Many minor power surges go completely unnoticed, and although you did not notice the surge, the surge protector will have filtered the power imbalance and lost a portion of its own protection (Joule reservoir). This can lead to a false sense of security as many protector boards will still function, albeit without any form of available protection. Inexpensive surge protectors often do not have any type of indicator to warn when their Joule reservoir is about to, or has been exceeded.

Re-set Buttons

Many surge protector and extension boards have a reset button. The reset button has nothing to do with surge protection or resetting the board after a power surge has occurred. Rather, the button is the reset for the circuit breaker which is for protection against a short circuit or over-load condition that could otherwise cause the wiring to melt with the board.

Main Types Of Power Surge

The following is an excerpt from Electrosafe, a company based in New Zealand.

Dropout

This is where a portion of the sine wave has a lower than expected value or is missing entirely, usually for a portion of a cycle. These types of problems can be caused when large motors are started, spot welders are operated, during lightning strikes, or when electrical equipment fails. Dropouts can lead to failures in computers and electronic equipment, reduced the life of motors and causing lights to flicker.

Power Failure

When the duration of a dropout exceeds 1 cycle it is usually referred to as a power failure, or blackout. This problem is usually the easiest to recognise.

Sag or Brownout

A power sag (or low line voltage) is a decrease in line voltage of at least 10% of the average line voltage for half a cycle or longer. The power sag is often caused by large inductive equipment, e.g. photocopy, bank of fluorescent lights. Sags can be caused by external factors as well, such as large power draining equipment used in other buildings.

Sags can be particularly detrimental to electronic equipment because of the malfunctions caused by the sudden decrease of available voltage to the power supply. Relays and solenoids can chatter generating spikes. Complete failure rarely occurs, however equipment lockup or lockout can occur requiring a resetting process.

Often equipment continues to operate, with the user, unaware of any problems that may have occurred.

Surge

A power surge is the opposite of a sag and is often referred to as ‘High Line Voltage’. A surge is defined as an increase in line voltage above 253 volts (on a 230V Line) for a half cycle or longer. Like the sag, the power surge is often caused by large inductive loads being applied on the same line. Power surges can cause some of the most dangerous situations, and their resulting damage is most difficult to repair.

Direct Relationship

There is a direct relationship between the amount of protection provided, the cost for that level of protection, and the price it is to replace the items destroyed. Furthermore, there is a convenience factor. How easy is it to replace and rewire the damaged component verses the cost of protection.

A generic extension board featuring back lit on/off button and a red LED, that when illuminated, instills confidence in the words 'surge protected'. This particular board does not have any form of surge protection and is not protected by a internal circuit breaker

Almost 'Spiritual' Protection

Some manufacturers of surge protectors often claim almost ‘spiritual’ protection; however, not every board is identical in the level of protection offered.

Inexpensive surge boards may only work once, and then not provide any indication to whether they have been damaged. Recall that many surges are invisible and only the surge protector will know a surge has occurred.

Other protectors do not provide high level protection, meaning that your equipment will be protected by a minor power surge, but not by a higher or continuous surge.

Many inexpensive power extension boards sport on their faceplate the writing ‘surge protected’. These boards are nothing more than glorified power boards and are not suitable for the protection of delicate equipment against any form a power surge.

Circuit Breakers Verses Surge Protection

A circuit breaker will provide an initial level of protection against a power surge – provided the circuit breaker trips, does not malfunction, and the intensity of the power surge is great enough to trigger the circuit breaker. However, a circuit breaker is NOT designed to filter electrical noise or minor power surges – these electrical imbalances will not trigger a circuit breaker and the electricity will travel to the power point and onward to any equipment attached to the power point. As discussed earlier, minor power surges are responsible for shortening the life of many components.

It should be remembered that although a circuit breaker will probably be triggered during a high volume or continuous power surge, the breaker may not trigger if the power surge is minimal. It also worth remembering that a circuit breaker does not trip immediately a power surge enteres its circuit. There is a millisecond or two delay. This delay can be enough for power to travel through the circuit breaker to any delicate equipment attched to a power point.

A circuit breaker is designed to trigger when there is an over amperage above the circuit breaker's rating. it protects the wires from over-amperage and overheating and potential for fire to occur. A surge protector - which may also incorporate a circuit breaker, is designed to protect/filter against power surges. Although both pieces of equipment are similar, there end uses are different.

I have used, for several years, surge protectors manufactured by Belkin. In general they were reliable and each unit provided two LED lights to warn if the device was not working. However, Belkin protectors have a limited life time based on their Joule reservoir, which in moderately priced units is around 525 Joules.

Novaris PP10A/4 surge filter. Simple LEDs indicate functionality of the unit while a push to reset circuit breaker button is located on the side of the unit. 4 power points facilitate connection of plugs or extension boards

Novaris Tasmania

Considering the expense and the amount of time that has been expended into building the simulator, I decided to up the ante and purchase a more solid and reliable system to protect against possible unwanted power surges, noise and spikes.

Novaris Tasmania sounds more in-line with something Stephen Hawkens has recently discovered and named in a far away galaxy; however, the name belongs to a Tasmanian company that develops and manufacturers surge protection equipment explicitly for industries that operate delicate equipment.

Two PP10A(4) surge filters manufactured by Novaris in Tasmania, Australia were commissioned. For those more technically or theoretically inclined, read the PP10A/4 specification sheet.

The simulator, with everything operational, draws very close to 10 amps; therefore, to stop the possibility of the household circuit breaker tripping if the 10 amp boundary is crossed, various simulator sectors are connected to two power points in two power zones. At each power point I have installed a PP10A/4.

The PP10A/4 enables four extension boards to be attached, which between two units, is more than enough to ensure that everything in the simulator is protected.

Complete Protection - Modems and Routers

Often forgotten is the need to also protect against unwanted noise and surges that may be transmitted along copper wires from the telephone line to the router, modem and switch box (assuming the simulator is connected to the Internet).

This may or not be an issue depending upon the type of wiring that has been used – older style copper wires have good conductivity; therefore, these wires will transmit the effects of a power surge; however, modern glass wire has minimal conductivity which lessons the opportunity for electricity to migrate.

Many surge protectors also provide protection in this area; however, as stated earlier the effectiveness of any surge protector to protect against unwanted power surges is dictated by its Joule reservoir.

Final Call

This post has focused, in the simplest terms, on the concept of household power distribution and the need for some type of surge protector. In a future post, I will discuss other methods of protecting delicate components from unwanted surges in power – in particular how to protect interface cards from damage from internal power spikes caused by computer power supply failures, reverse spiking, and grounding issues.

1 Murdering is a term used in the computer industry to describe when a process is stopped suddenly (such as turning the power off) without allowing the correct closing procedure to be followed.