Reverse Thrust Procedure

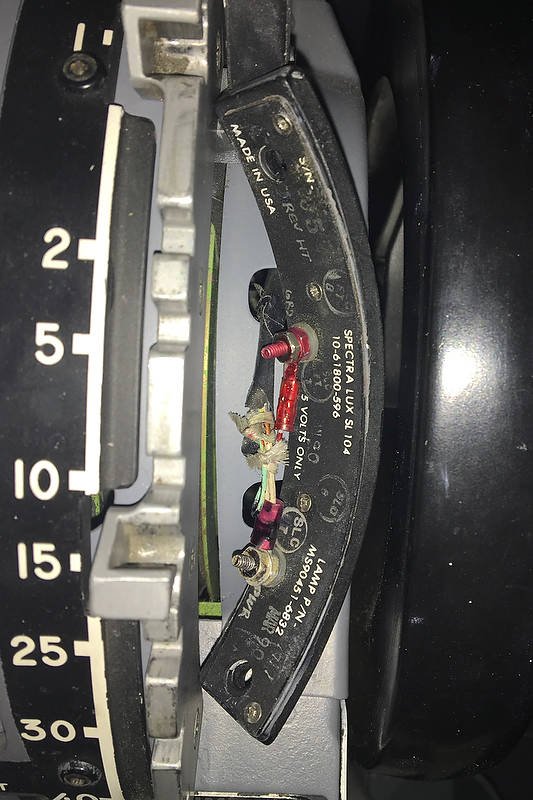

/The reverse thrust levers are clearly visible in the stowed position. OEM throttle quadrant converted for flight simulator use

Pilots tend to be numbers-orientated individuals. They like concise instructions and do not like ambiguity. Nor do they like being presented with something that is in ‘shades of grey’ rather than ‘black and white’.

When, how, and for how long to deploy the reverse thrust (reversers) falls into the 'grey area'.

In this article, I will endeavour to unravel some of the uncertainties as to when and how to use reverse thrust. I will also briefly discuss the relationship between the use of the autobrake and reverse thrust.

I am not going to delve deeply into every environmental consideration that needs to be analysed prior to the use of reverse thrust; this information is more than readily available from the Flight Crew Operations Manual (FCOM), Flight Crew Training Manual (FCTM) and other specific airline policy documentation.

Reverse Thrust Basics

Reverse thrust (reversers) is used only for ground operations and is used after touchdown to slow the aircraft; it is used to reduce the stopping distance, minimise brake temperatures and decrease wear and tear.

Reverse thrust comprises four détentes and an interlock position, that are engaged by moving the thrust levers from the stowed down position through to the fully up position.

No reverse thrust (thrust levers are closed / stowed position).

Detent 1 (idle reverse / thrust levers are at first position).

Detent 2 (thrust levers are at second position).

Full maximum reverse thrust (thrust levers are at fully upward position).

Between detent 1 and full maximum reverse thrust there is scope for the thrust levers to be positioned part way; thereby, altering the amount of thrust generated.

Schematic showing various positions for the thrust reverser levers

The interlock mechanism is felt when the reverse thrust levers are advanced to detent 1. The purpose of the interlock is to restrict movement of the reverse thrust lever until the reverser sleeves have approached the deployed position.

The procedure to use reverse thrust is very straightforward, however, questions arise as to whether to use detent 2 or full maximum reverse thrust, and when to begin reducing thrust and for how long.

Procedure

Following touchdown, without delay, move the reverse thrust levers to the interlock position and hold light pressure until the interlocks release (as the sleeves move rearwards).

For most landings, detent 1 and detent 2 will usually provide adequate reverse thrust (for normal operations). If additional reverse thrust is needed (wet, slippery or short field landing), full maximum reverse thrust can be selected by raising the thrust levers past detent 2 to full maximum reverse thrust.

To come out of reverse, the reverse thrust levers are returned to the detent 1 position, the engine allowed to spool down, and the levers then returned to the stow position.

Practically speaking, after touchdown maintain reverse thrust as required up to maximum thrust until the airspeed approaches 60 knots. Reverse thrust is then slowly reduced to detent 1 and then to reverse idle by taxi speed. Wait until the generated reverse thrust has bleed off, then slowly close the reversers and place them in the stow position.

Bringing the reverse thrust levers to detent 1 is important because it prevents engine exhaust re-ingestion and minimises the risk of foreign object debris (FOD) ingestion. Idle thrust also bleeds off forward thrust from the engines.

The autobrake is disarmed when a safe stop of the aircraft is assured, or when the aircraft reaches taxi speed.

Important Point:

If transitioning from using the autobrake to manual braking, use reverse thrust as required until reaching taxi speed and then disarm the autobrake.

Disarming the autobrake before closing reverse thrust provides a relativity seamless transition which increases passenger comfort (there is no aircraft jolt).

Conditions Required To Engage Reverse Thrust

The reversers can be deployed when either of the following conditions occur:

The radio altimeter senses less than 10 feet altitude;

When the air/ground sensor is in ground mode; and,

When the forward thrust levers are in the idle position.

Until these conditions occur, the movement of the reverse thrust levers is mechanically restricted and the levers cannot be moved into the aft position.

It is important to always deploy reverse thrust as soon as possible following touchdown. Do not wait for the nose wheel to touch down, but engage reverse thrust when the main wheels are on the runway. Timely deployment will increase stopping power; thereby, increasing safety and reducing heat build-up in the brake system.

A study determined that there was roughly a 17 second difference in stopping time when reverse thrust was deployed immediately the landing gear was on the runway as opposed to waiting several seconds for the nose gear to also be on the runway - reverse thrust is most effectual at high airspeeds and its effect decays on a linear scale as forward airspeed decreases.

Important Points:

Reverse thrust should always be used with the autobrake, unless the runway is exceptionally long without a possibility of runway overrun (the reason for this will be explained shortly).

When closing the reversers, always pause at detent 1. Monitor the REV thrust output on the Primary Engine Display (center panel) and stow the reversers only after reverse thrust has dissipated.

Call-outs

The pilot monitoring usually makes the following call-outs:

‘60 knots’;

‘Reversers normal’ - when both REV indications are green;

‘No reverser engine No: 1’ - if no REV indication or colour is amber; or,

‘No reverser engine No: 2’ - if no REV indication or colour is amber; or,

‘No reversers’ - if no REV indications or colour is amber.

NOTE: Annunciators and displays are discussed later in the article.

During landing, the pilot monitoring (PM) should call out 60 knots to advise the pilot flying (PF) in scheduling the reduction of reverse thrust.

When landings are in conditions that are suboptimal (heavy rain, snow, slush, etc), some operators stipulate that the PM operate and control the reverse thrust . This enables the PF to concentrate solely on the landing roll out rather than having the extra responsibility of also controlling the reverse thrust.

This said, although this procedure may lower pilot workload, it can cause problems when the PF is landing on a slippery runway or in marginal crosswind conditions. At these times, the PF may wish to use the reverse thrust in conjunction with the brakes and there is little time to call out instructions to the PM.

Technical Aspects (basic operation)

Each engine on the Boeing 737 Next Generation is equipped with an hydraulically operated thrust reverser, consisting of left and right translating (moving) sleeves. Aft movement of the reverser sleeves cause blocker doors to deflect fan discharge air forward, through fixed cascade vanes, producing reverse thrust.

Hydraulic pressure for the operation of the thrust reversers comes from hydraulic systems A and B, respectively. If hydraulic system A and/or B fails, alternate operation for the affected thrust reverser is available through the standby hydraulic system. When the standby hydraulic system is used, the affected thrust reverser deploys and retracts at a slower rate and some thrust symmetry can be anticipated.

When reverse thrust is selected an electro-mechanical lock is released. This causes the isolation valve to open which results in the thrust reverser control valve moving to the deploy position, allowing hydraulic pressure to unlock and deploy the reverser system.

The system is designed in such a way that an interlock mechanism restricts movement of the reverse thrust lever until the reverser sleeves are in the deployed position.

Closing the thrust levers past detent 1 to the stow position initiates the command to stow the reverser. When the lever reaches the full down position, the control valve moves to the stow position allowing hydraulic pressure to stow and lock the reverser sleeves. After the thrust reverser is stowed, the isolation valve closes and the electro-mechanical lock engages.

Relationship with Flaps

There is an interesting relationship between the use of reverse thrust and flaps 40.

When the aircraft has flaps 40 extended, the drag is greater requiring a higher %N1 to maintain airspeed. This higher N1 takes longer to spool down when the thrust levers are brought to idle during the flare; this enables more energy to be initially transferred to reverse thrust.

Therefore, during a flaps 40 landing more energy is available to be directed to reverse thrust, as opposed to a flaps 30 landing.

Annunciators and Displays

Thrust reverse indicators are displayed in the Primary Engine Display located in the center panel slightly above the No: 1 and No: 2 %N1 indicators. When reverse thrust is commanded, REV will be displayed initially in amber followed by green dependent upon the position of the thrust reverse levers.

Amber: Thrust reverser has been deployed from the stowed position and both sleeves have travelled ~10-90% to the deployed position.

Green: Thrust reverser has been deployed from the stowed position and both sleeves have travelled greater than 90% to the deployed position.

When either reverser sleeve moves from the stowed position, the amber REV indication annunciator, located on the upper display will illuminate. As the thrust reverser reaches the deployed position, the REV indication illuminates green and the reverse thrust lever can be raised to detent 2.

Electronic Engine Control (EEC) panel (AFT overhead). ProSim737 avionics suite virtual display

Additional reverse thrust annunciators are located on the aft overhead panel in the Electronic Engine Control (ECC) panel. These annunciators are triggered by the retraction of the reverse thrust levers to the stow position.

The annunciators will illuminate during a normal reverse thrust / stow operation for 10 seconds and then extinguish 10 seconds later when the isolation valve closes.

A system malfunction has occurred if the reverser (REV) annunciator illuminates at any other time, or illuminates for more than approximately 12 seconds (in the later instance, the master caution and ENG system annunciator will also illuminate).

Possible reasons for a system malfunction are that the isolation valve, thrust reverser control valve, or one or both of the thrust reverser sleeves are not in their correct position.

Autobrake and Reverse Thrust Use (the grey area)

Both the autobrake and timely application of reverse thrust can be used to slow the aircraft, however, both come at a cost.

Using the autobrake generates considerable heat in the braking system, translating to increased expenditure in maintenance and possible delays in turn around times (waiting for brakes to cool to operational temperature). Conversely, reverse thrust consumes excess fuel. Clearly there is a middle point where each will cancel out the other.

The immediate initiation of reverse thrust at main gear touchdown, and use of maximum reverse thrust, enable the autobrake system to reduce brake pressure to the minimum level – this is because the autobrake system senses deceleration and modulates brake pressure accordingly. Therefore, the proper application of reverse thrust results in reduced braking and less heat generation for a large portion of the landing roll.

Based on this premise, it stands to reason that this is why Boeing recommend to use the autobrake in conjunction with reverse thrust.

Boeing states in the FCTM that: ‘After touchdown, with the thrust levers at idle, rapidly raise the reverse thrust levers up and aft to the interlock position, then to reverse thrust detent 2. Conditions permitting, limit reverse thrust to detent 2’.

It appears to be Boeing’s intention to use reverse thrust as the major force to stop the aircraft, and as the use of maximum reverse thrust further minimises brake system heating, it would appear to be a preferred choice, despite the FCTM stating detent 2 is the preferred position for normal operations.

The official literature does not satisfactorily address this ‘grey area’ The result being that many 737 pilots use differing techniques when deploying and stowing the reversers.

Various Methods

If you observe how other pilots use the reversers, you will discover that there are several variations that follow the same theme.

1. A pilot will, when the aircraft passes through 60 knots, close reverse thrust by lowering the reverse thrust levers through detent 1 to the stow position without stopping at detent 1;

2. Try to locate detent 1 by ‘feel’ resulting in pushing the levers too far towards the stow position, causing forward thrust to unexpectedly occur momentarily;

3. Deliberately close maximum reverse thrust at the 60 knots by placing the reverse thrust levers into the stow position.

In the above three scenarios, the reverse thrust levers have not been allowed to pause at the detent 1 position. Pausing at detent 1 is important as %N1 requires several seconds to reduce to idle thrust after maximum reverse thrust has been used, and it is during this ‘wind down’ period, as the reverse sleeves fully close, that %N1 will transition through 55-60%N1, which is forward thrust.

By not allowing the reversers to pause momentarily at detent 1, to enable thrust to disparate below 55-60%N1, may cause the aircraft to momentarily accelerate. This can be rather disconcerting, especially on a short field landing or landing in marginal conditions.

So What Do I do (normal procedure)

At touchdown I engage reverse thrust – either detent 2 or maximum reverse thrust (or part thereof).

Approaching 60 knots I slowly and smoothly retard the reverse thrust levers to detent 1.

I always allow a few seconds at detent 1 to enable %N1 to dissipate.

Approaching taxi speed I disarm the speedbrake and close the reversers.

At no time do, unless in an emergency, do I close the reversers suddenly; I always close the reversers smoothly and slowly. This enables %N1 to dissipate gradually.

Final Call

The procedure to deploy reverse thrust is straightforward and very easy to accomplish, and there is little argument that reverse thrust should be used on all, but the longest runways in optimal environmental conditions. However, there is confusion and often disagreement to when the reversers are deployed, whether maximum reverse thrust should be used, and for how long the reversers should be left in the open position before retraction and stowing.

It is unfortunate that the information written in the Flight Crew Training Manual (FCTM) and Flight Crew Operations Manual (FCOM) does not provide a more objective ‘black and white’ answer to this procedural dilemma.

Video

The below video shows the REV indicators on the Primary Engine Display (when reverse thrust is commanded) and the REVERSE annunciators on the ECC panel (AFT overhead). Video taken directly from ProSim-AR 737 avionics suite (virtual software). Video upload to U-Tube rather than VIMEO).