Replacing Bulbs In The Boeing Fire Suppression Panel

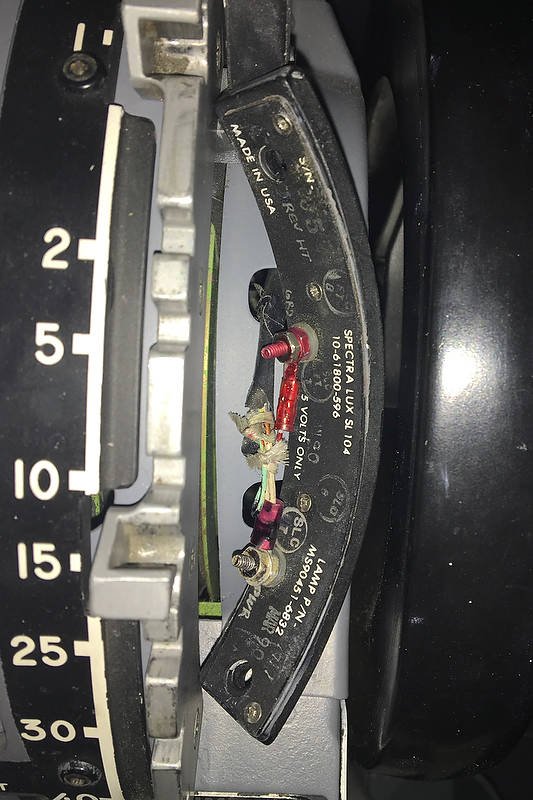

/Plastic cover removed and internal bulb holder raised to ninety degrees to facilitate bulb change. Note the lug on the side of the plastic cover. Boeing 737-800 Fire Suppression Panel

The Fire Suppression Panel (often called the fire handles) resides in the forward part of the center pedestal. The three fire handles control the fire suppression used to counter any fire that may develop in the engines or the auxiliary power unit (APU).

When a fire occurs, the fire bell will sound, the fire warning annunciator on the Master Caution System will illuminate, and the handle on the fire panel, that pertains to the particular engine or APU will illuminate.

The three red-coloured handles are illuminated by four 28 volt incandescent bulbs. These bulbs are very bright and if the bulbs are not extinguished soon after being illuminated the heat they generate can be substantial. Although the bulbs have an exceptionally long life cycle, regular testing of the fire handles (every flight) and heat can shorten their lifespan, facilitating a bulb replacement.

Clear covers removed showing four 28 Volt bulbs

Replacing Bulbs

To replace one or all of the bulbs the plastic red-coloured cover must be removed from the handle housing. This is done by carefully depressing the two 1 cm long lugs on each side of the plastic cover and pulling the cover off the housing. Often the covers can be brittle, especially if the panel is quite old and well used (heat from the bulbs and UV light can cause the plastic cover to become brittle) therefore, care should be taken when depressing the lugs.

When the cover has been removed, the internal bulb holder (which holds four bulbs) can be lifted out to ninety degrees; the bulbs can now be assessed Be aware that the bulb holder is not easily removable and is designed to swing out only to a ninety degree angle.

Bulb replacement can be by any voltage bulb, however, 28 volt bulbs are the norm. Using a lower voltage bulb will lower the illumination (and potential heat) and may make it easier to wire in a simulator environment because a dedicated 28 volt power supply is not required.

Amperage Draw

The amperage draw from 28 volt bulbs, for example during a lights test, is quite high (three handles, four bulbs in each handle is twelve bulbs), especially when combined with other bulbs being illuminated during the test. This is why a dedicated 28 volt power supply is recommended for the fire handles.

Important Point:

The two lugs on the plastic cover can be easily broken, especially if the plastic is slightly brittle.

Final Call

The fire panel used in the 737 Next Generation has changed little from its predecessors; why redesign something that works flawlessly. Bulb replacement is straightforward as long as care is taken when removing the plastic fire handle cover. Although 28 volt bulbs are the norm, replacement can be made by lower voltage bulbs if amperage draw or heat is considered a problem.