White Caps for Locking Toggle Switches on Overhead

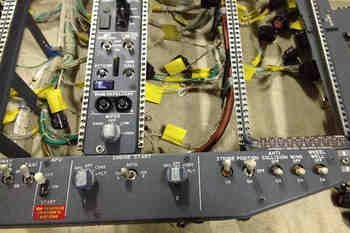

/Lower electrical panel showing reproduction latex-style cap (ELEC 2) and OEM Honeywell Switch Accessory 15PA90-6W (ELEC 1). For those with keen eyes - yes that is a voice recorder in the lower panel - more to follow in later posts. Of interest are the two different white caps (read main text)

It has taken a very long time to collect the assortment of OEM needed parts to complete the forward and aft overhead panels. Finally the build is now in progress and it’s hoped completion will be towards the end of 2016.

OEM Overhead Panel Switches (2 main types)

There are two main types of switches used on the forward and aft overhead panel. The push/throw switches (Honeywell switches pictured above) and the normal toggle-type switches. The Honeywell switches use a screw on white cap while the standard toggle switches use use a condom style white cap.

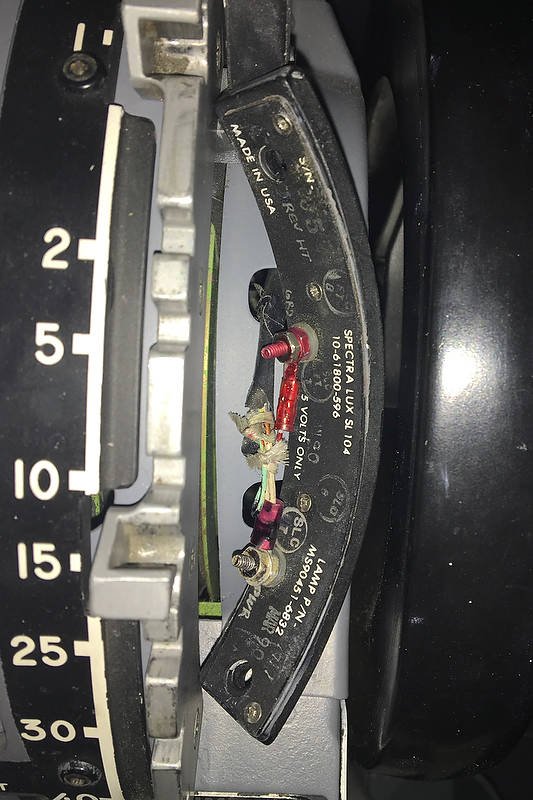

Honeywell Switch Accessory 15PA90-6W showing internal screw thread. The thread screws onto the stem of the toggle switch

Anatomy of the OEM White Cap

The Honeywell switch caps are not a slip-on latex cover but a solidly-produced head with an internal aluminium thread. The head is designed to be screwed directly to the shaft of the toggle switches. Firmly attached to this head is the white latex cap. This is the cap that is used on the push/throw switches.

Reproductions

Most of the reproduction white caps for the push / throw switches are either push-on style condoms, or a white-capped head attached to a slender hollow shaft. The shaft then slides over the existing switch stem.

The reproduction slip-on caps currently available on the market bear little resemblance to those made by Honeywell.

Important Point:

Bear in mind that the push / throw switches are used regularly and are usually forcefully manipulated; many reproductions do not stand up to continued abuse.

Choice - so many options

I had purchased several dozen OEM Honeywell toggle switches, however, for whatever reason the white caps on the toggles were either missing or damaged. Honeywell OEM switches are not inexpensive, so I was going to use reproduction white push-on caps (aka white condoms), but the caps failed to fit snugly to the OEM switches, and their appearance was slightly different to the OEM version - the ends of the caps looked rather bulbous.

My next choice was to use latex caps that are used in automotive industry. Once again, the appearance was slightly different and the automotive caps sported a small nipple at the end of each cap where they had been connected to the plastic retaining spur; I found the appearance of the nipple disconcerting.

Short of viable options, I purchased the OEM white caps from Honeywell which is the company that supplies Boeing. If you carefully look at the above picture of the lower electrical panel (click image to enlarge picture), you will observe the nearest toggle switch has been fitted with an automotive style cap; the nipple and joining line is clearly visible. The second toggle switch is fitted with the Honeywell white cap.

Installing the White Toggle Cap

To mount the white cap to a Honeywell switch you must first gently heat the switch stem. The heat will loosen the head of the toggle. It then is an easy matter to screw off the head and replace it with the OEM head. To heat the stem use either a hair dryer or paint dry gun (used to dry paint).

Measurements

Not everyone wants to utilise OEM parts. As such I have provided the measurements of the switch head (courtesy of Honeywell) for those who wish to try their hand at making their own white caps.

If you are searching for the other style of white caps used on the standard toggle switches, the part number for the correct condom white cap is 69-44578-2.

Reproduction Condoms - suppliers

For those not wishing to use OEM, there are several companies that manufacture reproduction white toggle caps. For example, PC Flights and GLB United Kingdom.

For further information see an earlier article: Toggle Condoms.

Glossary

Honeywell – Avionics conglomerate that is heavily involved in the defense and aviation industries.

OEM – Original Equipment Manufacture.